Описание

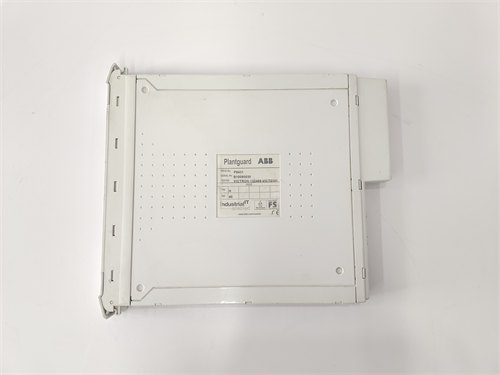

ABB P8431 DCS/PLC Module

Product Name:

ABB P8431 – Process I/O Module for Distributed Control Systems (DCS)

Product Description:

The ABB P8431 is an I/O module used in ABB’s Distributed Control System (DCS), specifically for applications within the 800xA system and other ABB process automation systems. It plays a vital role in providing process input/output (I/O) functionality, enabling the system to interface with field devices such as sensors, actuators, and other process equipment. The P8431 module is designed for reliable, high-performance data acquisition and control in real-time industrial process environments.

This module is part of the ABB 800xA I/O system and can handle both analog and digital I/O signals. The P8431 is engineered to meet the demanding requirements of industries such as oil and gas, chemical processing, power generation, and water treatment, where robust and high-speed I/O processing is required.

Key Features:

- Analog and Digital I/O: Supports both analog and digital inputs and outputs for versatile integration with a wide range of field devices.

- Real-Time Control: Ensures real-time data acquisition and processing, crucial for process control applications.

- High Reliability: Designed for reliable operation in industrial environments, ensuring stable performance even under harsh conditions.

- Modular Design: The P8431 module can be easily integrated into larger control systems, offering flexibility in system design and expansion.

- Redundant Power Supply Support: Supports redundant power supplies for increased system reliability and fault tolerance.

Product Parameters & Specifications:

-

Module Type: I/O Module for Distributed Control Systems (DCS)

-

Module Code: P8431

-

Module Series: ABB 800xA I/O System

-

Application Area: Process automation, real-time data exchange, control systems

-

Input/Output Types:

- Analog Inputs (AI):

- Number of Inputs: Up to 8 channels

- Input Range: Typically 0-20 mA, 4-20 mA, or 0-10 V

- Input Resolution: Typically 16-bit

- Analog Outputs (AO):

- Number of Outputs: Up to 4 channels

- Output Range: Typically 0-20 mA, 4-20 mA, or 0-10 V

- Output Resolution: Typically 16-bit

- Digital Inputs (DI):

- Number of Inputs: Up to 16 channels

- Input Type: Discrete on/off signals (e.g., contact closure or voltage level)

- Voltage Range: Typically 24V DC or 120V AC depending on configuration

- Digital Outputs (DO):

- Number of Outputs: Up to 16 channels

- Output Type: Relay or transistor outputs (depending on configuration)

- Output Voltage: Typically 24V DC or 120V AC

- Analog Inputs (AI):

-

Communication Protocols Supported:

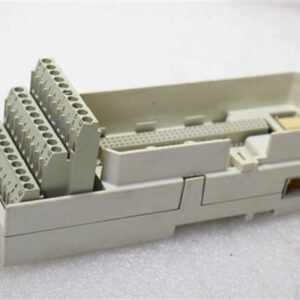

- Communication Interface: Integrated with ABB’s 800xA control system, supports various industrial communication protocols, such as Profibus DP, Modbus, Ethernet, and more.

- I/O Bus: The P8431 connects directly to the ABB 800xA system I/O bus to allow seamless data exchange with other system modules.

-

Power Supply:

- Operating Voltage: Typically 24V DC (standard in industrial automation)

- Power Consumption: Typically 10W – 20W depending on configuration and number of I/O points.

- Redundant Power Supply: Supports redundancy for increased system reliability.

-

Environmental Specifications:

- Operating Temperature: Typically -20°C to +60°C

- Storage Temperature: Typically -40°C to +85°C

- Humidity: 5% to 95%, non-condensing

- Vibration Resistance: Designed to meet standard industrial vibration resistance specifications

- Ingress Protection (IP Rating): Typically IP20 or IP65 (depending on the model and enclosure)

-

Physical Characteristics:

- Mounting: The module is designed for rack-mounting in the ABB 800xA system. It fits into the standard I/O chassis.

- Dimensions (L x W x H): The exact dimensions depend on the specific model and configuration but typically range from 150 mm x 100 mm x 40 mm.

- Weight: Approximate weight is 0.5 kg to 1 kg (depending on configuration).

-

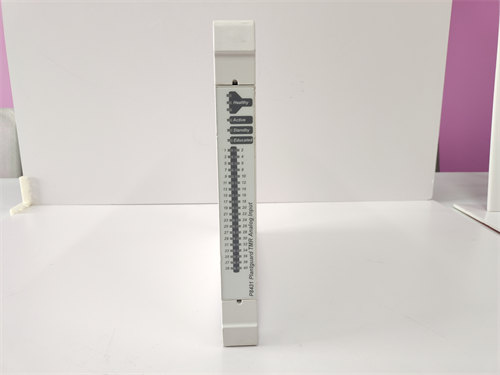

Status Indicators:

- LED Indicators: The P8431 module has built-in LED indicators to display the following statuses:

- Power status

- Communication status

- I/O channel status

- Fault and diagnostic indicators for troubleshooting

- Fault Diagnosis: Built-in diagnostics to detect I/O faults and module health, facilitating quick troubleshooting.

- LED Indicators: The P8431 module has built-in LED indicators to display the following statuses:

-

Redundancy and Fault Tolerance:

- Redundant Power Inputs for increased system reliability.

- Hot-Backup Support: In case of failure, the system can switch to a redundant I/O module without affecting the process.

Applications:

- Process Automation: Suitable for industries such as oil & gas, chemical processing, and power plants, where real-time data acquisition and control are critical.

- Energy Management Systems: Used in controlling and monitoring electrical power, HVAC, and water treatment systems.

- Safety Systems: Critical for interfacing with emergency shutdown systems, alarm systems, and safety monitoring systems.

- Manufacturing Automation: Can be integrated into production control, conveyor systems, and packaging lines.

- Remote Monitoring: Enables remote process monitoring and control via networked I/O interfaces, particularly when connected to ABB’s 800xA system.

Benefits:

- Versatility: Supports both analog and digital I/O signals, making it adaptable to a wide variety of field devices and applications.

- Reliability: Designed to operate in harsh industrial environments with built-in redundancy and diagnostics to reduce system downtime.

- Integration with ABB Systems: Seamlessly integrates with ABB’s 800xA control and automation system, providing a complete and optimized solution for process control.

- Scalability: The module can be easily expanded to meet the growing demands of large-scale industrial systems.

- Easy Maintenance: The built-in diagnostics and fault indicators simplify system troubleshooting and maintenance, ensuring minimal operational downtime.

Conclusion:

The ABB P8431 Process I/O Module is an essential component for ABB’s Distributed Control System (DCS), designed to offer reliable and real-time analog and digital I/O connectivity. It is ideal for use in demanding industrial environments where high-performance data acquisition and control are critical, such as in chemical processing, oil & gas, power generation, and other process automation applications. Its flexibility, reliability, and easy integration with ABB’s 800xA system make it a powerful solution for large-scale industrial automation.

Let me know if you need more details!