Описание

The ABB+500CPU05 1MRB150081R1/EDCS PLC Module is part of ABB’s AC500 PLC system, designed for industrial automation and process control applications. It offers high flexibility, processing power, and communication features, making it suitable for a wide range of applications in industries like manufacturing, energy, and infrastructure.

Here’s a breakdown of the ABB+500CPU05 PLC module, including its product name, description, parameters, and specifications:

Product Name:

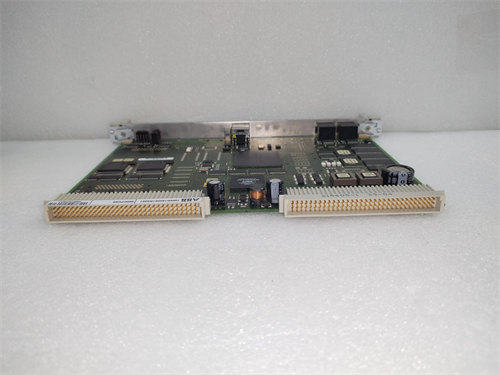

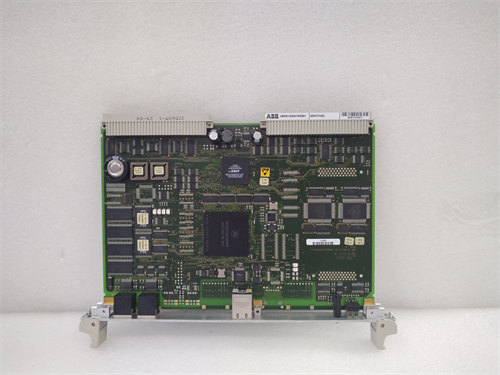

ABB+500CPU05 1MRB150081R1/EDCS PLC Module

Product Description:

The ABB+500CPU05 is a high-performance central processing unit (CPU) module for the AC500 PLC system, which is a modular, scalable control system used in industrial automation. It is the central control unit responsible for processing control logic, managing communication with I/O modules, and ensuring real-time performance in automation tasks.

The AC500 series is ideal for mid- to large-scale industrial applications requiring high-speed control, flexible I/O configurations, and seamless communication with field devices. The 500CPU05 specifically stands out for its powerful processing capability, integrated communication ports, and support for redundancy in mission-critical applications.

The 1MRB150081R1/EDCS version refers to a specific hardware revision and configuration, offering tailored features for applications requiring high reliability and advanced diagnostics.

Key Features:

- Powerful CPU Processing: The 500CPU05 offers advanced processing power for complex control algorithms.

- High-Speed Processing: Optimized for high-speed real-time control of machines, processes, and manufacturing systems.

- Communication Flexibility: Supports multiple communication protocols, including Ethernet and fieldbuses like Modbus, CANopen, and Profibus.

- Redundancy Options: Supports system redundancy for increased reliability and uptime in critical systems.

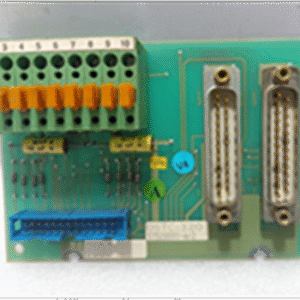

- Modular Design: Can be expanded with additional I/O modules, communication cards, and other system components to meet specific application needs.

- Integrated Diagnostics: Features built-in self-diagnostics and health monitoring for predictive maintenance and troubleshooting.

Product Parameters & Specifications:

1. General Specifications:

- Model: ABB+500CPU05 (1MRB150081R1/EDCS)

- System Type: AC500 PLC system.

- CPU Type: High-performance central processing unit.

- Control System: Distributed Control System (DCS) or Programmable Logic Controller (PLC).

- Form Factor: Designed for modular, expandable installations.

- Target Applications: Industrial automation, process control, energy management, machine automation, and building automation.

2. Electrical Specifications:

- Operating Voltage: Typically 24V DC.

- Power Consumption: Approx. 10-15W depending on system configuration.

- Signal Types:

- Digital Inputs/Outputs: 24V DC logic.

- Analog Inputs: 0-10V or 4-20mA, used for sensors like temperature, pressure, and flow.

- Analog Outputs: 0-10V or 4-20mA for controlling external devices (e.g., actuators, motors).

- Relay Outputs: For controlling high-power devices.

3. Communication Interfaces:

- Ethernet Ports: Typically includes 2 Ethernet ports for networking and communication with external systems.

- Fieldbus Options: Supports several protocols such as:

- Modbus RTU/TCP

- Profibus DP

- CANopen

- DeviceNet

- Serial Ports: For connection to serial devices and communication with legacy systems.

- OPC Support: Allows communication with other systems and devices through the OPC standard.

4. Performance Specifications:

- Processor: The CPU typically has a high-speed processor capable of executing complex control algorithms and I/O processing in real-time.

- Scan Time: Typically 1ms to 5ms for each cycle depending on the configuration and load.

- Memory: Can vary from 512MB to 2GB depending on the specific model and configuration.

- Program Memory: Typically capable of storing a significant amount of ladder logic, function blocks, and system configurations.

5. I/O Support:

- I/O Modules: Supports a wide range of digital and analog I/O modules, expandable to meet system requirements.

- Modular Expansion: Can be expanded with various input/output and communication modules to support large, complex systems.

- I/O Density: Can support a high density of I/O devices within a compact system architecture.

6. Environmental Specifications:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F), but variants may support extended ranges.

- Storage Temperature: -40°C to 85°C (-40°F to 185°F).

- Humidity: Designed for operation in 5% to 95% relative humidity, non-condensing.

- Shock Resistance: Typically 15g shock resistance, suited for rugged industrial environments.

- Vibration Resistance: Supports 5g vibrations for durability in harsh environments.

7. Redundancy & Fault Tolerance:

- Redundant Power Supply: 500CPU05 typically offers support for dual power supplies, ensuring uninterrupted operation in case of power failure.

- Redundant CPUs: Hot standby configuration available for high availability in mission-critical applications.

- System Diagnostics: Includes built-in diagnostics and fault detection features, including network status indicators, for predictive maintenance and failure prevention.

8. Safety and Security Features:

- Safety Integrity Level (SIL): Certain versions of the CPU support SIL 3 for functional safety applications (e.g., emergency shutdown systems, process safety control).

- Security: Features integrated security mechanisms like password protection, user access control, and secure remote access to protect against cyber threats.

Application Areas:

- Manufacturing Automation: Used in assembly lines, robotic systems, and material handling systems for real-time monitoring and control.

- Energy Management: Ideal for renewable energy systems, substation automation, and energy grid management.

- Oil & Gas: Applied in pump control, valve regulation, and flow monitoring in oil and gas pipelines and refineries.

- Building Automation: Used in HVAC systems, lighting control, and fire detection in large buildings and campuses.

- Process Industries: Controls processes in chemical plants, water treatment facilities, and pharmaceutical manufacturing.

Conclusion:

The ABB+500CPU05 1MRB150081R1/EDCS PLC Module is a versatile and reliable controller within the AC500 PLC system. Its high-speed processing, flexible I/O configurations, and multiple communication interfaces make it an ideal choice for complex industrial automation tasks across a wide range of sectors, including manufacturing, energy, and process industries. With its built-in redundancy features and integrated diagnostics, it ensures high reliability and minimum downtime in critical applications.