Описание

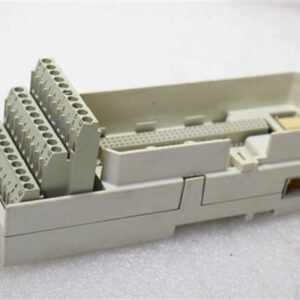

ABB PFVK135 DCS PLC Module

Product Name:

ABB PFVK135 DCS PLC Module

Product Description:

The ABB PFVK135 is a high-performance Distributed Control System (DCS) module designed to meet the stringent requirements of modern industrial automation. Manufactured by ABB, a global leader in power and automation technologies, this module is specifically engineered to handle a wide range of process control and monitoring tasks across various industries, including oil & gas, power generation, chemical processing, and manufacturing.

The PFVK135 module is designed to provide exceptional control, monitoring, and diagnostic features for critical equipment in industrial processes. It integrates seamlessly into ABB’s extensive DCS solutions, offering high-speed data collection, flexible I/O configurations, and advanced diagnostics, ensuring maximum uptime and efficiency in mission-critical systems.

Product Parameters:

- Model Number: PFVK135

- Manufacturer: ABB (A leading global power and automation technology company)

- Type: DCS PLC Module

- System Compatibility: Compatible with ABB’s 800xA DCS and other ABB control systems

- Power Supply:

- Nominal Voltage: 24V DC (Standard for industrial automation equipment)

- Power Consumption: Varies depending on configuration, typically 10W to 20W

- Operating Temperature:

- Range: -20°C to +60°C, designed for industrial environments

- Weight: Approx. 1.2 kg, depending on the configuration and specific I/O options

- Environmental Conditions:

- Humidity: Up to 95% (non-condensing)

- Vibration Resistance: Meets industrial vibration standards for harsh environments

Specifications:

-

I/O Configuration:

- Digital Inputs (DI): Up to 32 channels (for binary signals such as switches and relays)

- Digital Outputs (DO): Up to 32 channels (for controlling actuators, relays, etc.)

- Analog Inputs (AI): Up to 16 channels (for continuous measurement of physical quantities like pressure, temperature, or flow rate)

- Analog Outputs (AO): Up to 16 channels (for controlling actuators like valves and motors)

-

Processor:

- Real-time Control: The PFVK135 module processes control algorithms with minimal latency, ensuring precise control for critical industrial operations.

-

Communication Protocols:

- Ethernet/IP: High-speed communication for real-time control and data transfer.

- Modbus: A widely used protocol for remote device communication in industrial networks.

- Profibus: Used for communication between the DCS module and field devices such as sensors, actuators, and other control systems.

- HART: For communication with smart field devices like transmitters and controllers.

-

Redundancy:

- Offers redundant communication and power supply configurations to enhance system reliability and ensure continuous operation in critical environments.

-

Memory:

- The PFVK135 includes sufficient onboard memory for control logic, data logging, diagnostics, and configuration parameters.

-

Diagnostic Capabilities:

- Self-Diagnostics: The module includes self-monitoring and diagnostic features, allowing users to detect faults and irregularities early.

- Event Logging: Logs critical system events for troubleshooting, predictive maintenance, and performance analysis.

-

Safety Standards:

- Meets SIL 2 and SIL 3 standards for safety-critical applications, offering reliability and compliance for safety systems in hazardous environments.

Key Features:

-

Real-Time Control and Monitoring:

Provides fast, accurate monitoring and control for process-critical parameters in industrial applications. -

Flexibility in I/O Configuration:

Supports both digital and analog I/O configurations to meet the specific control requirements of various processes. -

Advanced Diagnostics and Fault Detection:

Includes advanced diagnostic tools for proactive monitoring of system health, early fault detection, and maintenance optimization. -

Redundant and Reliable Design:

Features redundancy in power supply and communication to ensure uninterrupted operation even in case of component failure. -

Industry Protocol Support:

Supports communication protocols like Ethernet/IP, Modbus, Profibus, and HART, allowing for easy integration with existing control systems and field devices. -

Safety Compliance:

Meets SIL 2/SIL 3 safety standards, making it suitable for use in safety-critical applications. -

Compact and Robust Design:

The module is designed to endure harsh environmental conditions, such as high humidity, temperature fluctuations, and vibration, common in industrial environments.

Applications:

The ABB PFVK135 DCS PLC Module is ideal for a variety of industrial applications, including:

- Oil & Gas: Monitoring and control of equipment like pumps, compressors, and turbines used in upstream, midstream, and downstream oil and gas operations.

- Power Generation: Control of power plant systems, including turbines, generators, and grid management.

- Chemical Processing: Monitoring and controlling reactors, distillation columns, and pumps in chemical production.

- Water Treatment: Used in water treatment plants to manage filtration systems, chemical dosing, and distribution networks.

- Manufacturing: Industrial automation, process control, and real-time monitoring of production lines in sectors like automotive, food and beverage, and pharmaceuticals.

Conclusion:

The ABB PFVK135 DCS PLC Module is a versatile and reliable control module designed for industrial applications requiring real-time monitoring and process control. Its support for a wide range of communication protocols, redundant configurations, and advanced diagnostic features makes it ideal for mission-critical environments in industries such as oil and gas, power generation, and chemical processing. The module’s flexibility, scalability, and robust design ensure that it can handle the demands of modern industrial automation while maintaining high levels of safety and reliability.