Описание

Product Name:

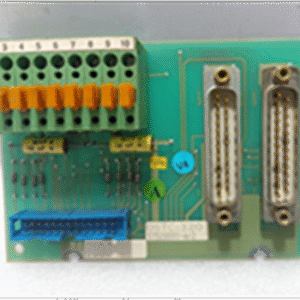

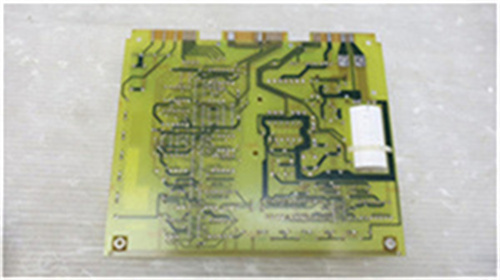

EMERSON VE4003S2B1 DCS/PLC Module

Product Description:

The EMERSON VE4003S2B1 is a high-performance DCS (Distributed Control System) / PLC (Programmable Logic Controller) module designed for complex industrial process control applications. Manufactured by Emerson, this module is part of the Emerson DeltaV system, known for providing reliable, flexible, and scalable solutions in industries such as oil & gas, chemical processing, pharmaceuticals, power generation, and water treatment.

The VE4003S2B1 module supports the real-time monitoring, control, and automation of a wide variety of industrial processes. It provides a robust interface for I/O (Input/Output) devices, sensors, actuators, and controllers within a distributed control architecture. With advanced diagnostic capabilities, redundancy options, and high reliability, the module is engineered to meet the demanding requirements of industries where safety, uptime, and performance are crucial.

Designed to integrate seamlessly with other modules within the Emerson DeltaV DCS platform, the VE4003S2B1 module ensures smooth data exchange and system optimization for a wide range of automation tasks.

Key Features:

- Real-Time Control & Monitoring: Supports high-speed real-time control and provides a continuous flow of process data for accurate decision-making.

- Modular and Scalable: Easily integrated with other Emerson DeltaV modules, offering scalability for future system expansions.

- Advanced Diagnostics & Predictive Maintenance: Offers continuous self-monitoring with built-in diagnostics to reduce downtime and predict potential system failures.

- Redundancy Support: Designed with redundant configurations for critical applications to ensure fault tolerance and system availability.

- Integrated Communication Protocols: Supports Modbus, Ethernet/IP, and Emerson’s proprietary communication protocols, enabling seamless communication with field devices and control systems.

- Flexible I/O Configuration: Supports various digital and analog I/O configurations for diverse process applications.

Product Parameters & Specifications:

1. General Specifications:

- Model: EMERSON VE4003S2B1

- Type: DCS/PLC I/O Module

- Application: Designed for process automation in industries such as oil & gas, chemical processing, power generation, water treatment, and pharmaceuticals.

- System Compatibility: Part of the Emerson DeltaV DCS system, supporting integration with other DeltaV control and communication modules.

- Form Factor: Rack-mountable for installation in DeltaV cabinets, supporting centralized or distributed control configurations.

2. Electrical Specifications:

- Operating Voltage: 24V DC, commonly used in industrial control applications.

- Power Consumption: Approximately 15W to 40W, depending on the module configuration and active features.

- Signal Types:

- Digital Inputs: 24V DC logic level.

- Analog Inputs: 4-20mA or 0-10V for sensors.

- Analog Outputs: 4-20mA or 0-10V for controlling actuators.

3. I/O Specifications:

- Digital Inputs: Supports up to 64 digital inputs (depending on configuration).

- Digital Outputs: Up to 64 digital outputs, typically used for controlling devices such as relays, motors, and solenoids.

- Analog Inputs: Can support up to 32 analog inputs with 4-20mA or 0-10V signals for continuous process control (e.g., pressure, temperature, flow rate).

- Analog Outputs: Up to 32 analog outputs, suitable for controlling equipment like actuators, valves, and variable-speed drives.

4. Communication Protocols:

- Ethernet/IP: Provides high-speed data communication for integration with other automation systems and industrial devices.

- Modbus RTU/TCP: Ensures compatibility with third-party field devices for control and monitoring applications.

- Proprietary Emerson Communication Protocols: Ensures smooth integration within the DeltaV system, optimizing data flow and system performance.

- Serial Communication (RS-232/RS-485): Enables serial communication for linking to legacy devices or remote control systems.

5. Environmental Specifications:

- Operating Temperature Range: Typically -20°C to 60°C (-4°F to 140°F).

- Storage Temperature Range: -40°C to 85°C (-40°F to 185°F).

- Humidity: Designed to operate in 5% to 95% relative humidity, non-condensing.

- Vibration Resistance: Typically rated for 5g vibration acceleration.

- Shock Resistance: Typically rated for 10g shock resistance.

- Ingress Protection: IP20, suitable for environments with limited exposure to dust or moisture.

6. Performance Specifications:

- Scan Time: 10ms to 100ms scan rate, depending on system load and module configuration.

- Processor: The module includes a high-performance microprocessor for executing real-time control tasks and handling large datasets.

- Memory: The VE4003S2B1 module is equipped with 512MB to 2GB of memory, sufficient for storing configuration data, control programs, and diagnostic information.

- Redundancy: Supports redundant communication paths and power supplies for high availability in mission-critical applications.

7. Safety and Diagnostic Features:

- Built-in Diagnostics: Continuously monitors the health of the module, identifying potential issues before they affect system performance.

- Predictive Maintenance: Provides early warning of system faults through diagnostic data, allowing for predictive maintenance and reducing downtime.

- Hot-Swappable: Designed for hot-swapping during maintenance without requiring system downtime, improving overall system availability.

- Redundant Power Supplies: Supports dual power supplies for high-reliability applications, reducing the risk of system outages due to power failure.

Application Examples:

- Oil & Gas: Applied in wellhead control systems, oil refineries, and pipeline monitoring, ensuring continuous, real-time control of production processes.

- Chemical Processing: Used in chemical reactors, distillation columns, and mixing systems, where precise control of temperatures, pressures, and flow rates is critical.

- Power Generation: Supports turbine control, generator management, and plant automation in power stations.

- Water Treatment: Applied in water purification systems, wastewater treatment plants, and desalination facilities, optimizing the operation of pumps, filters, and valves.

- Pharmaceuticals: Utilized in the control of batch processes in pharmaceutical production, ensuring compliance with regulatory standards and maintaining consistent product quality.

Conclusion:

The EMERSON VE4003S2B1 DCS/PLC Module is a versatile, high-performance control module for industrial automation applications, providing real-time control, advanced diagnostics, and high system reliability. Whether used in oil & gas, chemical processing, power generation, or water treatment, it integrates seamlessly into Emerson’s DeltaV DCS platform, ensuring efficient and reliable operations. With support for redundant configurations, predictive maintenance, and advanced communication protocols, the VE4003S2B1 module is designed to meet the needs of demanding, mission-critical industrial applications.