Описание

The FOXBORO FBM218 is a part of Foxboro’s I/A Series, which is a widely used system for process control and automation in various industries such as oil and gas, chemical processing, pharmaceuticals, and power generation. The FBM218 is specifically designed for handling analog and digital signals in distributed control systems (DCS). Below is a detailed breakdown of the FOXBORO FBM218 DCS PLC Module.

Product Name:

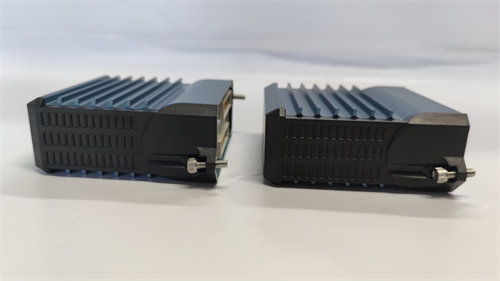

FOXBORO FBM218

Part Number: FBM218 (may vary with configuration)

Product Description:

The FOXBORO FBM218 is an Input/Output (I/O) Module for the Foxboro I/A Series DCS (Distributed Control System). This module is designed to facilitate the communication of analog and digital signals between field instruments (such as transmitters, sensors, and switches) and the control system. It is built to ensure precise control and monitoring of industrial processes, with applications spanning process control, monitoring, and safety systems.

The FBM218 integrates easily with Foxboro’s DCS architecture, enabling users to manage both analog and digital data in real-time. The module ensures a high degree of accuracy, reliability, and safety in critical process industries, where seamless operation and minimal downtime are paramount.

Product Parameters:

- Module Type: I/O Module for Analog and Digital Signal Processing

- Compatible System: Foxboro I/A Series Distributed Control System (DCS)

- Signal Types Supported:

- Analog Inputs/Outputs (AI/AO): 4-20mA, 0-10V DC

- Digital Inputs/Outputs (DI/DO): Discrete signals for control and monitoring

- Module Configuration: Can be configured to support different combinations of analog and digital I/O channels depending on application needs.

- Mounting Type: Typically mounted on a DIN rail within a control cabinet.

- Power Supply: Typically 24V DC (common across many Foxboro I/A series modules)

- Communication Protocol: Compatible with Foxboro’s communication protocols, such as Fieldbus and Modbus (for communication with other systems)

Specifications:

General Features:

-

Input/Output Channels:

- Analog Input (AI): Up to 16 channels (configurable based on the module type).

- Analog Output (AO): Typically up to 4 channels (configurable based on the application).

- Digital Inputs (DI): Typically supports up to 16 channels.

- Digital Outputs (DO): Typically supports up to 8 channels.

-

Signal Accuracy: High-precision analog inputs with accuracy typically in the range of ±0.1% of full scale.

-

Signal Types:

- Analog I/O: 4-20mA, 0-10V DC, RTD, Thermocouple (depending on model configuration).

- Digital I/O: Dry contact, voltage pulses, and logic signals.

-

Data Conversion: High-speed, real-time analog-to-digital (A/D) and digital-to-analog (D/A) conversion for accurate process monitoring and control.

-

Resolution:

- Analog Inputs: 12-bit or higher for high-resolution measurement.

- Analog Outputs: 12-bit or higher for accurate signal reproduction.

Electrical Specifications:

-

Power Supply: Typically 24V DC (nominal voltage, with a tolerance range of 20-30V DC).

-

Power Consumption: Approximately 5-10W depending on the configuration and load.

-

Signal Conditioning: Built-in signal conditioning for various sensor inputs (such as RTD, thermocouple, etc.).

-

Isolation: Typically features electrical isolation between the field side (input/output) and the control system side for protection against voltage spikes or ground loops.

Environmental Specifications:

-

Temperature Range:

- Operating Temperature: Typically -20°C to 60°C (-4°F to 140°F), depending on environmental conditions.

- Storage Temperature: -40°C to 85°C (-40°F to 185°F).

-

Humidity: Designed to operate in environments with 5% to 95% relative humidity, non-condensing.

-

Vibration: Can withstand typical industrial vibrations (as per IEC/EN 60068 standards).

-

Safety: Certified for use in industrial environments with safety features that ensure compliance with international standards (e.g., CE, UL, IECEx).

Communication Protocols:

- Fieldbus Communication: Compatible with Foxboro’s proprietary fieldbus protocols for easy integration with the I/A Series system.

- Modbus RTU/TCP: Optional integration with Modbus-based systems for remote monitoring or control applications.

Applications:

-

Process Control:

- Suitable for controlling and monitoring industrial processes such as those found in chemical plants, oil refineries, and power plants.

- Supports PID control, feedback loops, and real-time process data acquisition.

-

Data Acquisition:

- Collects data from various sensors (e.g., temperature, pressure, flow) and transmits it to the DCS for processing.

-

Monitoring and Diagnostics:

- Enables real-time diagnostics for system performance, facilitating predictive maintenance and improving uptime.

-

Safety Systems:

- Can be integrated into Safety Instrumented Systems (SIS) to ensure compliance with safety standards such as IEC 61508 and IEC 61511.

-

Batch and Continuous Process Control:

- Used in both batch processes (where operations are performed in discrete steps) and continuous processes (where operations run in a constant, uninterrupted flow).

Benefits:

- Scalability: Flexible I/O configurations to adapt to varying process requirements, providing easy expansion and modification.

- High Accuracy: High-precision measurement and control capabilities, ensuring consistent and reliable process control.

- Ease of Integration: Seamless integration with Foxboro I/A Series DCS and other control systems.

- Reliability: Designed for high availability, ensuring minimal downtime in critical industrial applications.

- Advanced Diagnostics: Built-in diagnostics and health monitoring to ensure continuous operation and simplify troubleshooting.

- Safety: Supports compliance with stringent industrial safety standards, helping avoid hazardous situations in critical processes.

Conclusion:

The FOXBORO FBM218 DCS PLC Module is a versatile, high-performance I/O module designed to handle both analog and digital signals in industrial environments. It is an essential part of the Foxboro I/A Series DCS, offering advanced process control, safety, and diagnostics. Its high accuracy, scalability, and easy integration make it ideal for industries where reliability and precision are critical, such as oil and gas, chemical processing, and power generation.

Let me know if you need further details or specific configuration options!