Описание

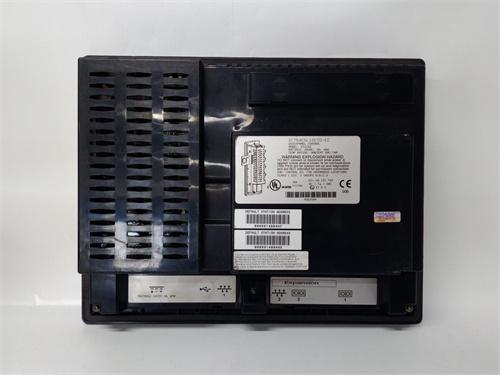

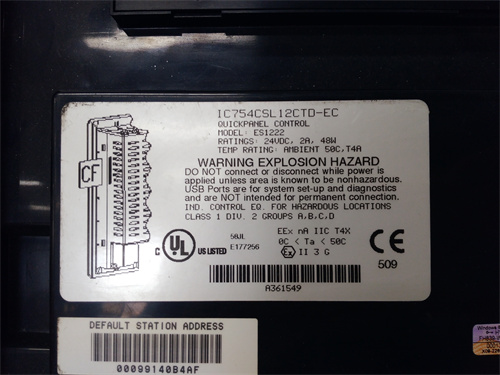

Product Overview: GE IC754CSL12CTD

Technical Parameters of GE IC754CSL12CTD

| Parameter | Value/Characteristic |

|---|---|

| Device Type | Industrial HMI terminal, GE Proficy Machine Edition HMI series |

| Display | • Size: 12.1-inch color touchscreen

• Resolution: 800×600 pixels (SVGA) • Brightness: 350 cd/m² • Touch Technology: Resistive (2-point touch) • Operating Temperature Range: 0°C – 50°C |

| Communication Protocols | • Supported Protocols: Modbus TCP, EtherNet/IP, GE SRTP (for Series 90-30/70 PLCs)

• Network Port: 1×Ethernet RJ45 (10/100 Mbps) • Serial Port: 1×RS-232/485 (for legacy devices) • Data Transfer Latency: <100ms (to GE PLCs) |

| Compatibility | • GE PLCs: Series 90-30 (IC693CPU363), Series 90-70, VersaMax (IC200CPU001)

• Third-Party Controllers: Siemens S7-1200/1500, Allen-Bradley Micro800 • Software: GE Proficy Machine Edition v9.0+ |

| Power Supply | • Input Voltage: 24V DC (±10%)

• Power Consumption: ≤25W • Protection: Reverse polarity protection (diode-based), overvoltage protection (up to 30V DC) |

| Physical & Environmental | • Dimensions (W×H×D): 320mm × 245mm × 55mm

• Weight: ≤1.8kg • Mounting: Panel-mount (IP65 front panel, IP20 rear) • Vibration Resistance: ≤5Hz (continuous), ≤15Hz (intermittent, ≤5min) |

| Certifications | CE, UL 508, IEC 61131-3, EN 61000-6-2, RoHS |

Advantages and Features of GE IC754CSL12CTD

-

Intuitive Visualization and Operation

The 12.1-inch high-brightness touchscreen of the GE IC754CSL12CTD ensures clear visibility even in bright factory lighting (350 cd/m²), while the resistive touch technology works reliably with gloves—critical for food processing or automotive environments where operators wear protective gear. Customizable dashboards (via GE Proficy Machine Edition) let users prioritize key data (e.g., alarm counts, throughput) for quick decision-making.

-

Seamless Integration with GE Ecosystem

Unlike generic HMIs, the GE IC754CSL12CTD natively supports GE’s SRTP protocol, eliminating the need for additional gateways when connecting to Series 90-30/70 PLCs. This integration reduces data latency to <100ms and ensures consistent parameter synchronization—for example, adjusting a conveyor’s speed via the HMI updates the GE IC693CPU363 controller instantly, avoiding production delays.

-

Rugged Design for Industrial Environments

With an IP65-rated front panel, the GE IC754CSL12CTD resists dust and water splashes, making it suitable for wet environments (e.g., beverage bottling plants). The device also withstands temperature fluctuations (0°C – 50°C) and vibration, ensuring uninterrupted operation in facilities with heavy machinery (e.g., metal stamping lines).

-

Data Logging and Alarm Management

The GE IC754CSL12CTD stores up to 30 days of historical data (configurable via software) and categorizes alarms by severity (critical, warning, informational). Operators can view alarm timestamps and root causes (e.g., “Conveyor 2 overcurrent”) directly on the touchscreen, reducing troubleshooting time by up to 40% compared to text-only HMIs.

Application Cases of GE IC754CSL12CTD

-

Automotive Component Assembly Line

A tier-1 automotive supplier uses the GE IC754CSL12CTD to monitor 4 robotic arms (for welding door hinges) and 2 conveyors. The HMI displays real-time robotic joint temperatures (to prevent overheating) and conveyor part counts. If a hinge is misaligned, the GE IC754CSL12CTD triggers a critical alarm, pauses the robot, and shows a step-by-step guide to reposition the part—reducing defect rates from 2% to 0.5%.

-

Food & Beverage Juice Bottling Plant

In a citrus juice bottling facility, the GE IC754CSL12CTD controls mixing tank temperature (via a GE IC693MDL742 module) and filling volume. Operators use the touchscreen to set the mixing temperature to 35°C (optimal for juice extraction) and adjust filling nozzles to 500ml. The HMI logs daily production (e.g., 10,000 bottles/day) and alerts managers if filling accuracy drops below 99.8%—ensuring compliance with food safety standards.

-

Chemical Mixing Process Control

A chemical plant uses the GE IC754CSL12CTD to monitor 3 mixing tanks (for detergent production) where temperature (20°C – 60°C) and pH levels (6.5 – 7.5) are critical. The HMI displays real-time pH readings (from GE IC693MDL753 analog input modules) and allows operators to adjust chemical dosages remotely. If pH exceeds 7.5, the GE IC754CSL12CTD automatically reduces the alkaline additive flow, preventing batch rejection.

Comparison with Competitors

| Parameter | GE IC754CSL12CTD | Siemens KTP1200 Basic (6AV2123-2MA03-0AX0) | Allen-Bradley PanelView Plus 7 1250 (2711P-T12C4D8) |

|---|---|---|---|

| Display | 12.1-inch, 800×600, 350 cd/m² | 12-inch, 800×600, 300 cd/m² | 12-inch, 1024×768, 350 cd/m² |

| GE PLC Compatibility | Native (SRTP protocol, no gateway) | Requires adapter (Modbus TCP) | Requires driver (EtherNet/IP) |

| Data Latency (to PLC) | <100ms | ~150ms | ~120ms |

| Front Panel Protection | IP65 | IP65 | IP65 |

| Historical Data Storage | Up to 30 days | Up to 14 days (standard) | Up to 21 days (standard) |

Selection Recommendations and Precautions

-

Selection Recommendations: Choose the GE IC754CSL12CTD if:

- You operate GE PLCs (Series 90-30/70, VersaMax) and need seamless HMI-PLC integration without additional hardware/software.

- Your application requires a rugged, glove-compatible touchscreen (IP65 front, resistive touch) for harsh environments (food processing, automotive assembly).

- You need long-term data logging (up to 30 days) to track production trends or comply with regulatory requirements (e.g., food safety audits).

-

Precautions:

- Use only a 24V DC power supply (±10%)—connecting to higher voltages (e.g., 110V AC) will damage the GE IC754CSL12CTD.

- Ensure the front panel is mounted correctly to maintain IP65 protection—gaps between the HMI and panel will allow dust/water ingress.

- Update the GE IC754CSL12CTD firmware via GE Proficy Machine Edition quarterly—firmware updates fix protocol bugs and improve compatibility with new PLC models.

- Avoid mounting the HMI near high-voltage equipment (e.g., transformers) or sources of vibration (e.g., large motors)—electromagnetic interference (EMI) or vibration can cause screen flickering or data loss.

IC754CSL12CTD