Описание

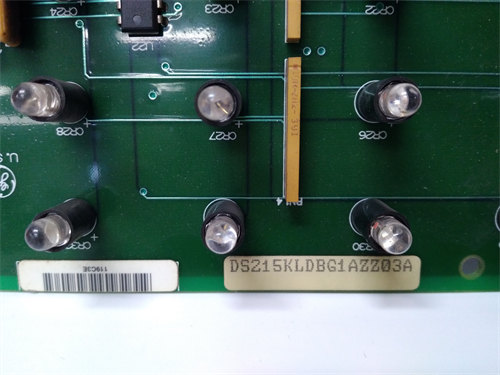

Product Name:

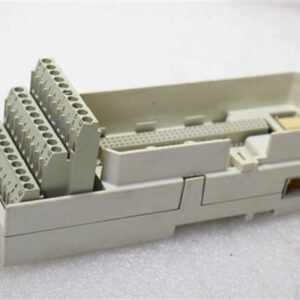

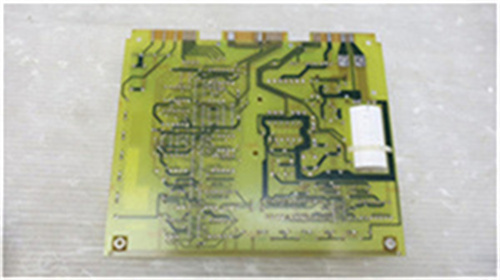

GE DS200KLDBG1ABC DCS/PLC Module

Product Description:

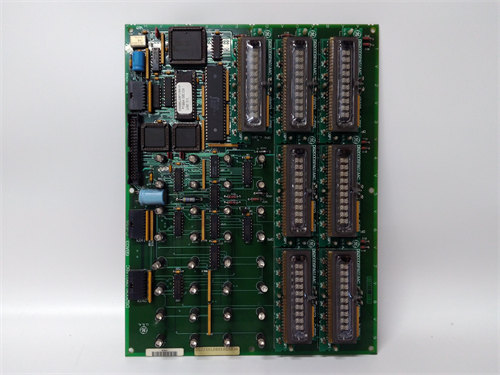

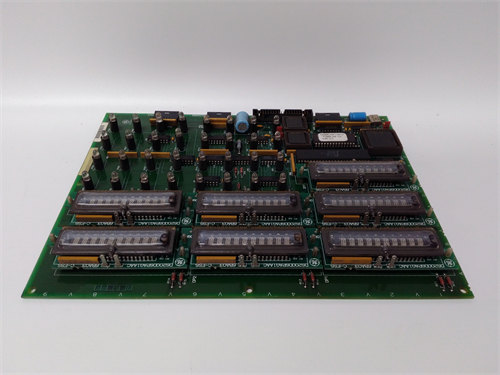

The GE DS200KLDBG1ABC is a Distributed Control System (DCS) or Programmable Logic Controller (PLC) module designed by General Electric (GE) for industrial automation and process control applications. This module is part of GE’s Mark VIe and Mark VI systems, which are commonly used in power generation, oil & gas, chemical processing, and other mission-critical industries.

The DS200KLDBG1ABC serves as an integral component for controlling various I/O operations and managing real-time data to ensure the efficient operation of large-scale, automated industrial systems. Built with redundancy and fault tolerance in mind, this module is capable of providing seamless control even in the event of hardware failure, making it suitable for applications that require high availability and reliability. Additionally, the module supports diagnostics and troubleshooting capabilities, which are crucial in industries where safety and continuous operation are vital.

Key Features:

- High Availability and Redundancy: The DS200KLDBG1ABC is designed to work in redundant configurations, offering high reliability in critical applications. If one module fails, the system can continue to operate seamlessly.

- Real-Time Control: Enables real-time data processing, which is essential for maintaining the precision and efficiency of automated processes.

- Diagnostics: Comes equipped with advanced self-diagnostics and error detection features to ensure that issues are identified early and resolved before they lead to significant problems.

- Modular Architecture: Can be integrated with other components within the GE control system, ensuring scalability and flexibility for different industrial automation requirements.

- Versatility: Supports a variety of industrial applications, including power plants, oil rigs, manufacturing, and chemical processing.

Product Parameters & Specifications:

1. General Specifications:

- Model: GE DS200KLDBG1ABC

- Type: DCS/PLC Module

- Manufacturer: General Electric (GE)

- Application: Industrial automation and control in power generation, energy, oil & gas, and manufacturing industries.

- System Compatibility: Compatible with GE Mark VIe and Mark VI control systems.

- Module Type: I/O module that interfaces with sensors, actuators, and other field devices.

2. Electrical Specifications:

- Operating Voltage: Typically operates on 24V DC, commonly used in control systems for industrial automation.

- Power Consumption: The power consumption depends on the configuration but typically falls between 15W and 40W.

- Input Voltage Range: Operates within the 24V DC range, which is standard in industrial control environments.

- Output Voltage: Typically provides 24V DC for powering field I/O devices.

- I/O Voltage: Supports 24V DC for digital inputs/outputs and 4-20mA for analog inputs/outputs.

3. I/O Specifications:

- Digital Inputs: Supports 16 to 64 digital inputs, which can handle various sensors, switches, and signal sources.

- Digital Outputs: Typically provides 16 to 64 digital outputs for controlling relays, valves, actuators, and other field devices.

- Analog Inputs: Compatible with 4-20mA or 0-10V analog sensors for measuring physical parameters such as pressure, temperature, and flow.

- Analog Outputs: Provides 4-20mA or 0-10V outputs for controlling actuators and other equipment.

- Redundancy: Can be configured with redundant I/O systems for ensuring system reliability and uptime.

4. Communication Protocols:

- Modbus: Supports Modbus RTU and Modbus TCP, allowing communication with a variety of field devices and control systems.

- Ethernet/IP: High-speed Ethernet communication protocol used for transmitting data in real-time between the control system and external devices.

- Profibus: Provides robust field-level communication with Profibus-enabled devices.

- GE Profinet: Enables high-performance communication for industrial Ethernet systems and PLCs.

- Redundant Communication: Supports redundant communication for increased reliability and fault tolerance.

5. Environmental Specifications:

- Operating Temperature: Typically supports a temperature range of -20°C to 60°C (-4°F to 140°F) for industrial environments.

- Storage Temperature: The module can be stored within a range of -40°C to 85°C (-40°F to 185°F) without damage.

- Relative Humidity: Designed to operate in environments with 5% to 95% non-condensing humidity.

- Vibration Resistance: The system is built to meet industrial standards for vibration, typically up to 5g.

- Shock Resistance: Can withstand shocks up to 10g for reliable operation in industrial conditions.

- Ingress Protection: The module typically has an IP20 protection rating, which is standard for industrial control modules.

6. Performance Specifications:

- Scan Time: Offers fast scan times, typically in the range of 10ms to 50ms, allowing for real-time control and data processing.

- Processor Speed: Uses 32-bit or 64-bit processors for efficient data handling and control.

- Memory: Includes 512MB to 2GB of memory, depending on configuration and the size of the control system.

- Control Capacity: Can handle up to 50,000 to 100,000 control points, making it suitable for medium to large-scale industrial systems.

7. Safety Features:

- SIL (Safety Integrity Level): The module can be configured for SIL 2 or SIL 3 applications, ensuring compliance with safety standards for critical industrial processes.

- Fault Detection: Continuous diagnostic monitoring and error detection ensure that the system is safe to operate and that potential issues are detected early.

- Redundant Systems: Supports redundant power supplies, processors, and I/O for high availability and reduced downtime in case of failure.

- Hot Swap: Modules can be replaced while the system is still operational, ensuring no downtime during maintenance.

Application Examples:

- Power Plants: Used in the control and automation of turbines, generators, and other critical power plant equipment.

- Oil & Gas: Employed in offshore platforms, refineries, and pipeline management for real-time data processing and control.

- Chemical Processing: Manages the continuous production processes in chemical plants by ensuring that parameters like temperature, pressure, and flow remain within safe operating ranges.

- Manufacturing: Applied in assembly lines, robotics, and other automated production environments where precision control is needed.

- Water Treatment Plants: Monitors and controls the various stages of water purification and distribution, ensuring regulatory compliance and operational efficiency.

Conclusion:

The GE DS200KLDBG1ABC DCS/PLC Module is a highly reliable, flexible, and scalable solution designed for industrial control and automation. With its real-time processing, modular architecture, and advanced diagnostic features, it is ideally suited for mission-critical applications in industries such as power generation, oil & gas, manufacturing, and chemical processing. Its redundancy features, fault tolerance, and high availability ensure continuous, safe, and efficient operation in complex systems.