Описание

Product Name:

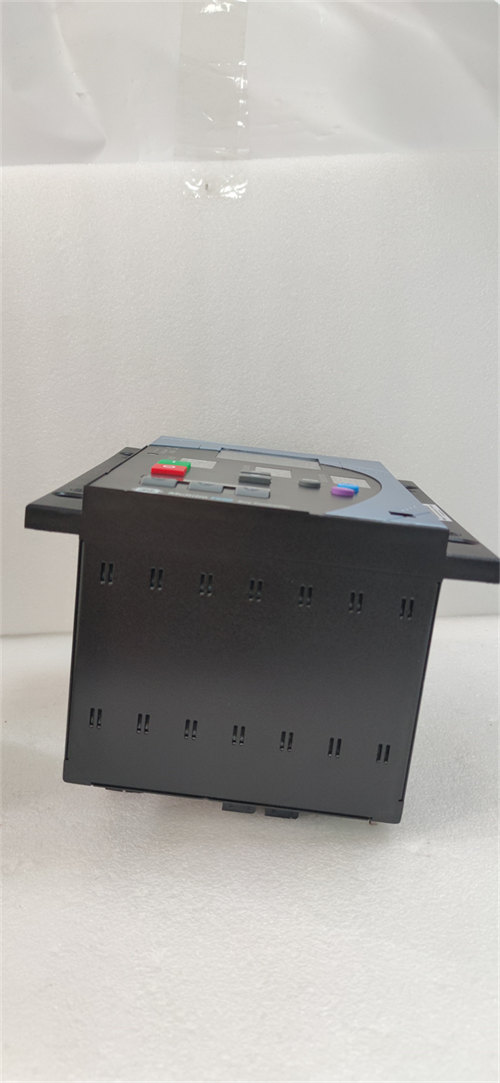

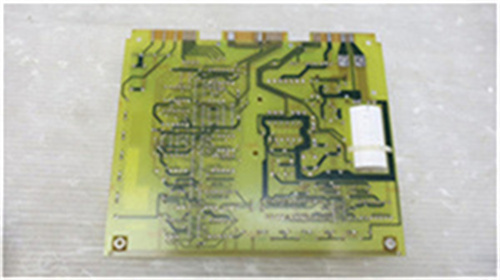

GE+F650-G-N-A-B-F-2-G-1-HI-C-E DCS PLC Module

Product Description:

The GE+F650-G-N-A-B-F-2-G-1-HI-C-E is a sophisticated Distributed Control System (DCS) module designed for high-end industrial applications. Manufactured by General Electric (GE), this module is part of their advanced F650 series, built to provide reliable, real-time control for complex industrial automation and process control tasks.

Primarily used in sectors such as power generation, petrochemical, and chemical plants, the F650-G-N-A-B-F-2-G-1-HI-C-E module offers features such as redundant processing capabilities, advanced diagnostics, and modular I/O configurations, ensuring that it can withstand demanding operating conditions while providing seamless performance.

This module also integrates a high level of flexibility and scalability, supporting varied communication protocols and offering high availability with advanced fault tolerance. The system ensures that operational continuity is maintained, even under the most challenging scenarios.

Product Parameters & Specifications:

General Specifications:

- Model: GE+F650-G-N-A-B-F-2-G-1-HI-C-E

- Type: DCS (Distributed Control System) PLC Module

- Manufacturer: General Electric (GE)

- Primary Application: Industrial process control and automation

- System Integration: Part of the GE F650 DCS system, tailored for advanced, high-performance control and monitoring in industrial environments.

- Communication: Supports a range of communication protocols for seamless integration with other control systems.

Key Features:

- Redundant Architecture: Built with a redundant design, allowing for fail-safe operation and ensuring system availability even in the event of a component failure.

- Scalable and Modular: The system is designed to support large-scale industrial operations, with customizable configurations for I/O modules and system components.

- High Availability: The module offers robust fault tolerance mechanisms, ensuring that operational uptime is maintained, even under extreme conditions.

- Advanced Diagnostics: Real-time diagnostics provide detailed information for predictive maintenance, fault identification, and troubleshooting, minimizing downtime.

- Wide Temperature Range: Designed for use in harsh industrial environments, with a broad