Описание

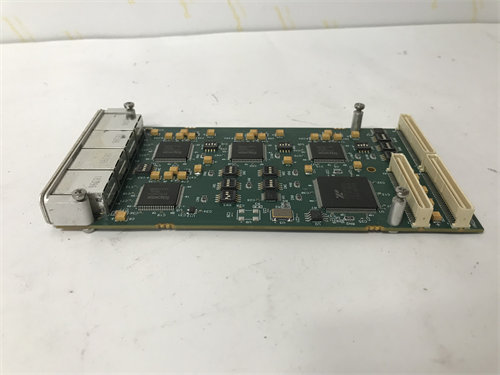

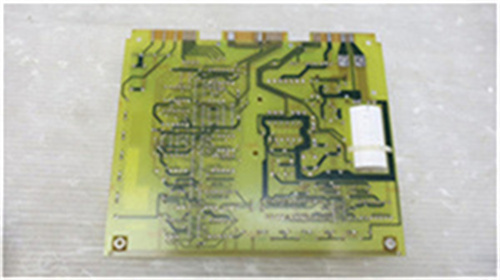

GE+PMC422-LAM D2 DCS PLC Module

Product Name:

GE+PMC422-LAM D2 DCS PLC Module

Product Description:

The GE+PMC422-LAM D2 is a high-performance Distributed Control System (DCS) module designed by General Electric (GE), a global leader in automation and control systems. The PMC422-LAM D2 module provides versatile and scalable control for industrial automation applications, particularly in process control environments. This module is designed to offer superior real-time control, fault detection, and diagnostics in mission-critical applications across industries such as oil and gas, power generation, chemical, and manufacturing.

As part of GE’s Process Control and Automation solutions, the PMC422-LAM D2 integrates seamlessly with the GE Mark VIe DCS platform and is specifically engineered for both large-scale and complex automation systems. The module supports a variety of communication protocols, offers extensive I/O configuration flexibility, and ensures high availability and reliability for industrial operations.

Product Parameters:

- Model Number: PMC422-LAM D2

- Manufacturer: General Electric (GE)

- Type: DCS PLC Module (Programmable Logic Controller for Distributed Control System)

- System Compatibility: Compatible with GE Mark VIe DCS, GE Control Systems, and GE Fanuc PLC platforms.

- Power Supply:

- Nominal Voltage: 24V DC (typically used in industrial control systems)

- Power Consumption: Typically 10W to 25W, depending on the configuration

- Operating Temperature:

- Range: -20°C to +60°C, designed for rugged industrial environments

- Weight: Approx. 1.5 kg (varies by configuration)

- Humidity: Up to 95% non-condensing

- Vibration: Meets industrial vibration resistance standards

Specifications:

-

I/O Configuration:

- Digital Inputs (DI): Up to 32 channels, typically used for on/off signals from field devices

- Digital Outputs (DO): Up to 32 channels, for controlling relays, actuators, or indicators

- Analog Inputs (AI): Up to 16 channels for continuous measurement of process parameters like temperature, pressure, and flow

- Analog Outputs (AO): Up to 16 channels for precise control of actuators, such as valves or motors

- Special I/O: Includes specialized input/output options for high-speed or safety-critical applications

-

Processor:

- High-speed processing with minimal latency, capable of executing control algorithms in real time

- Supports complex control applications like PID control, advanced process control, and regulatory functions

-

Communication Protocols:

- Ethernet/IP: For high-speed communication and integration with Ethernet-based control networks

- Modbus TCP/IP & RTU: Provides compatibility with a wide range of field devices using the Modbus protocol

- Profibus DP: For integration with field devices in distributed control systems

- HART: Supports smart field instruments, enabling seamless integration with intelligent devices like smart transmitters

- GE DCS Integration: Fully integrates with GE’s Mark VIe and other DCS platforms for centralized control and monitoring.

-

Redundancy:

- Supports redundant communication links and power supply configurations for ensuring continuous operation even during component failure.

- Redundant network architecture for high availability in critical control applications.

-

Memory:

- Onboard volatile and non-volatile memory for control logic, historical data storage, and configuration parameters.

-

Diagnostic Features:

- Includes advanced diagnostics for fault detection, predictive maintenance, and system health monitoring.

- Event Logging: Provides logs of important system events for troubleshooting and performance analysis.

- Self-Diagnostics: Capable of detecting faults in hardware and I/O connections, providing early warnings to prevent system failure.

-

Safety Compliance:

- Supports SIL 2 and SIL 3 (Safety Integrity Level) for safety-critical applications, ensuring that the system can perform safety functions in hazardous environments.

Key Features:

-

Real-Time Control and Monitoring:

Designed for real-time process control, with fast data processing and minimal latency for precision control. -

Modular and Scalable:

Can be customized with a range of I/O configurations to meet the specific needs of different applications. -

Comprehensive Diagnostics and Fault Detection:

Equipped with self-diagnostics, predictive maintenance capabilities, and detailed event logging for early detection of potential issues. -

Wide Protocol Support:

Supports various communication protocols, such as Ethernet/IP, Modbus, Profibus, and HART, enabling easy integration with existing field devices and control systems. -

Redundancy for High Availability:

Offers redundant communication and power supply options for mission-critical operations, ensuring continuous performance in industrial environments. -

Safety Standards Compliance:

Meets SIL 2/SIL 3 standards for safety systems, making it ideal for hazardous process environments. -

Compact, Robust Design:

Designed to withstand harsh industrial environments with features like vibration resistance and wide temperature tolerance. -

Advanced Process Control:

Suitable for advanced control algorithms such as PID control, model predictive control (MPC), and adaptive control.

Applications:

The GE+PMC422-LAM D2 DCS PLC Module is designed for use in various critical industries:

- Oil & Gas: Control of extraction processes, pipeline management, and refinery automation.

- Power Generation: Integration with turbine control systems, boiler monitoring, and grid management.

- Chemical Processing: Managing reactors, distillation processes, and chemical mixing.

- Water Treatment: Monitoring and controlling filtration systems, chemical dosing, and distribution networks.

- Manufacturing: Used in factory automation systems, production lines, and machinery control for industries such as automotive, food & beverage, and pharmaceuticals.

Conclusion:

The GE+PMC422-LAM D2 DCS PLC Module is a high-performance control solution offering real-time control, advanced diagnostics, and extensive I/O capabilities. Its robust design, coupled with high communication flexibility, makes it ideal for complex industrial automation applications that require reliability, redundancy, and safety. With its integration into GE’s Mark VIe DCS platform, this module is a critical component for industries that demand high availability, precision, and fault tolerance in mission-critical operations.