Описание

Product Name:

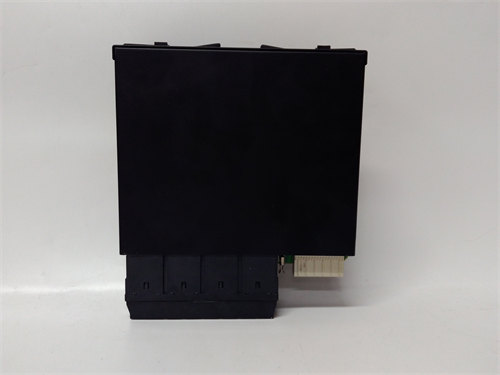

GE+UR6PH DCS PLC Module

Product Description:

The GE+UR6PH is a highly reliable and versatile Distributed Control System (DCS) module designed for process automation and industrial control in various industries such as oil and gas, chemical manufacturing, power generation, and petrochemical plants. This module is part of the GE automation portfolio and is engineered for seamless integration into industrial control systems, offering robust control and monitoring features while meeting stringent industrial requirements.

The GE+UR6PH module supports a range of programmable logic control (PLC) functionalities while being designed with fault-tolerant features to ensure continuous operation. It can handle complex control processes, providing the reliability and scalability needed for large-scale industrial automation systems.

Product Parameters & Specifications:

General Specifications:

- Model: GE+UR6PH

- Type: DCS (Distributed Control System) PLC Module

- Manufacturer: General Electric (GE) Automation and Controls

- Primary Use: Industrial process control, automation, and monitoring

- Module Integration: Part of GE’s DCS/PLC systems (part of a scalable modular control system for plant-wide applications)

- Functionality: High-performance, fault-tolerant PLC/DCS module for process control in industrial environments.

Key Features:

- Fault-Tolerant Design: The GE+UR6PH module is built for high availability and system robustness with redundancy and fault tolerance to support continuous industrial operation.

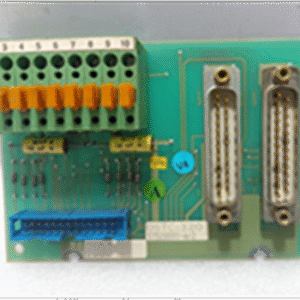

- Flexible I/O Configuration: The module supports a wide range of digital and analog I/O modules, offering flexibility for different types of control systems and operational needs.

- Advanced Process Control: It enables precise and real-time process control, perfect for industries with strict operational requirements, such as oil and gas or chemical production.

- Scalable System: Designed for large-scale industrial environments, it supports the expansion of I/O and processing power as needed, making it suitable for both small and large control systems.

- Real-Time Diagnostics and Monitoring: Continuous monitoring and diagnostic capabilities help operators to detect faults early and take corrective actions quickly.

- Integrated Communication: The module supports various communication protocols for smooth integration with other devices, including Modbus, Ethernet, and RS-485.

Electrical Specifications:

-

Power Supply:

- Voltage: Typically operates with 24V DC power.

- Redundancy: Power supply redundancy is possible to ensure the reliability of the module in case of power failure.

-

Power Consumption:

- Low power consumption to ensure energy efficiency for continuous operation.

-

Input Voltage Range:

- Standard operating voltage range is 24V DC, with wide tolerance to handle industrial power conditions.

-

Communication Protocols:

- Supports Modbus for industrial communication and Ethernet for high-speed data transfer and system integration.

- RS-485 for serial communication.

Mechanical Specifications:

-

Form Factor:

- Typically designed for rack-mounted installation within 19-inch standard control racks.

-

Dimensions:

- Approximate dimensions include height: 3U and depth: around 200mm, but exact dimensions depend on the specific model and configuration.

-

Cooling:

- Designed for passive cooling with the need for proper ventilation in industrial racks to maintain temperature regulation.

-

Weight:

- Typically between 1.5 to 2.5 kg, depending on the configuration.

Environmental Specifications:

-

Operating Temperature:

- Typically rated for -20°C to +60°C. Extended temperature ranges may be available for harsher environments.

-

Storage Temperature:

- -40°C to +85°C for safe transportation and storage in various climates.

-

Relative Humidity:

- The system generally operates within 5% to 95% non-condensing relative humidity.

-

Vibration and Shock Resistance:

- Designed to meet industrial vibration and shock standards, making it reliable in harsh operational environments.

-

Ingress Protection:

- Modules are typically housed in an IP20 rated enclosure, offering basic protection against dust and accidental contact.

Functional Specifications:

-

I/O Support:

- Modular I/O configuration that supports a wide range of digital and analog input/output modules for flexible system design and application.

- The module supports high-speed I/O processing for real-time control and monitoring.

-

Redundancy:

- Redundant processors and communication links to ensure system reliability and fault tolerance.

- Built-in redundant power supplies and communication channels to minimize downtime and maximize uptime.

-

Safety and Fault Detection:

- Advanced diagnostic features allow continuous real-time monitoring of the system’s health.

- The module has built-in fault detection mechanisms to flag issues and take corrective actions automatically, ensuring system safety.

-

Real-Time Monitoring and Diagnostics:

- Provides real-time diagnostics of the system and process variables, which ensures the stability and reliability of the process.

-

Control and Automation:

- Used for critical process control and automation tasks such as PID control, sequence control, and regulation of flow, temperature, pressure, etc.

Software and Configuration:

-

Configuration Software:

- Configured through GE proprietary software, such as Proficy iFIX or Proficy CIMPLICITY, which provides an intuitive interface for system configuration, monitoring, and diagnostics.

- The system supports graphical programming and easy-to-understand logic configurations for ease of use and implementation.

-

Diagnostics and Troubleshooting:

- Integrated diagnostic tools that allow remote troubleshooting and event logging, helping maintenance teams identify and resolve issues quickly.

Applications:

-

Oil & Gas:

- Used in upstream and downstream applications, including wellheads, pipelines, and refineries, to ensure safe and reliable control of industrial processes.

-

Chemical and Petrochemical:

- Ideal for chemical plants where precision control is required to maintain safety and optimize processes.

-

Power Generation:

- Applied in power plants to control turbines, generators, and other critical equipment.

-

Manufacturing and Industrial Automation:

- Suitable for various manufacturing environments where precise control over production lines is needed.

-

Water Treatment and Utilities:

- Used for controlling and monitoring water treatment plants, pump stations, and other utilities that require high reliability and automation.

Conclusion:

The GE+UR6PH DCS PLC Module provides robust, high-performance control and automation features for industrial process control. With redundant configurations, fault tolerance, and real-time diagnostics, it offers the reliability needed for mission-critical applications. This module is particularly suited for industries such as oil & gas, chemical manufacturing, and power generation, where precision, safety, and uptime are essential for successful operations.