Описание

Общая характеристика продукта

Модуль GE 201CI-1 представляет собой компактное устройство, устанавливаемое в крейт (шасси) контроллера Series 90-30. В зависимости от конкретной конфигурации, он может быть:

- Модулем дискретного ввода (Digital Input – DI): Принимает сигналы от внешних устройств, таких как кнопки, концевые выключатели, датчики приближения, и передает их состояние (ВКЛ/ВЫКЛ) в процессор контроллера.

- Модулем дискретного вывода (Digital Output – DO): Принимает сигналы от процессора и управляет внешними нагрузками, такими как реле, сигнальные лампы, катушки пускателей.

Модуль 201CI-1 является ключевым компонентом для взаимодействия ПЛК с реальным миром. Работа любой автоматизированной системы, от конвейера до станка, начинается с получения или выдачи сигналов через такие модули, как дискретный модуль ввода-вывода GE 201CI-1.

Параметры продукта

Модуль GE 201CI-1 представляет собой компактное устройство, устанавливаемое в крейт (шасси) контроллера Series 90-30. В зависимости от конкретной конфигурации, он может быть:

- Модулем дискретного ввода (Digital Input – DI): Принимает сигналы от внешних устройств, таких как кнопки, концевые выключатели, датчики приближения, и передает их состояние (ВКЛ/ВЫКЛ) в процессор контроллера.

- Модулем дискретного вывода (Digital Output – DO): Принимает сигналы от процессора и управляет внешними нагрузками, такими как реле, сигнальные лампы, катушки пускателей.

Модуль 201CI-1 является ключевым компонентом для взаимодействия ПЛК с реальным миром. Работа любой автоматизированной системы, от конвейера до станка, начинается с получения или выдачи сигналов через такие модули, как дискретный модуль ввода-вывода GE 201CI-1.

-

Hydraulic characteristics:

- Type — 4-way proportional servo valve with feedback control;

- Operating pressure range — 10–35 MPa;

- Maximum flow rate — 120 L/min;

- Response time (90% of signal) — ≤20 ms;

- Control spool type — lapland-style with pressure compensation.

-

Electrical characteristics:

- Control signals — 4–20 mA (analog), PROFINET (digital);

- Supply voltage — DC 24 V (18–30 V);

- Current consumption — ≤350 mA;

- Isolation — 2500 V AC (between electronics and hydraulic section).

-

Operational characteristics:

- Housing material — alloy steel 4140;

- Protection class — IP65 (external components);

- Operating temperature range — -20 °C to +70 °C;

- Mean Time Between Failures (MTBF) — ≥200,000 hours;

- Compatible fluids — mineral oils (ISO VG 32–68), synthetic esters.

Преимущества и особенности

- High dynamic performance: MOOG G413-604A delivers a response time of ≤20 ms, making it ideal for applications requiring rapid adjustments, such as dynamic testing of automotive suspension systems or precision pressing operations where load changes occur frequently.

- Pressure-compensated design: The integrated pressure compensation ensures consistent flow rates regardless of fluctuations in supply pressure, maintaining stability in systems with variable load conditions — a key advantage in metal forming presses.

- Dual protocol support: Compatibility with both analog (4–20 mA) and digital (PROFINET) signals allows MOOG G413-604A to integrate seamlessly with legacy and modern automation systems, reducing retrofitting costs.

- Robust construction: The alloy steel housing and IP65 protection class ensure resistance to vibration, dust, and moisture, making it suitable for harsh industrial environments like foundries or offshore platforms.

- Predictive diagnostics: Built-in condition monitoring features transmit real-time data on valve performance, enabling proactive maintenance and minimizing unplanned downtime. Additional application examples are available at: .

Модуль GE 201CI-1 представляет собой компактное устройство, устанавливаемое в крейт (шасси) контроллера Series 90-30. В зависимости от конкретной конфигурации, он может быть:

- Модулем дискретного ввода (Digital Input – DI): Принимает сигналы от внешних устройств, таких как кнопки, концевые выключатели, датчики приближения, и передает их состояние (ВКЛ/ВЫКЛ) в процессор контроллера.

- Модулем дискретного вывода (Digital Output – DO): Принимает сигналы от процессора и управляет внешними нагрузками, такими как реле, сигнальные лампы, катушки пускателей.

Модуль 201CI-1 является ключевым компонентом для взаимодействия ПЛК с реальным миром. Работа любой автоматизированной системы, от конвейера до станка, начинается с получения или выдачи сигналов через такие модули, как дискретный модуль ввода-вывода GE 201CI-1.

Примеры применения в отраслях

- Aerospace (flight simulation): In full-motion flight simulators, MOOG G413-604A controls hydraulic actuators that replicate aircraft movements, with its rapid response (≤20 ms) ensuring realistic handling characteristics. Signals from a Siemens S7-1500 PLC via PROFINET synchronize valve operation with simulator software. Specific case studies are available at: .

Модуль GE 201CI-1 представляет собой компактное устройство, устанавливаемое в крейт (шасси) контроллера Series 90-30. В зависимости от конкретной конфигурации, он может быть:

- Модулем дискретного ввода (Digital Input – DI): Принимает сигналы от внешних устройств, таких как кнопки, концевые выключатели, датчики приближения, и передает их состояние (ВКЛ/ВЫКЛ) в процессор контроллера.

- Модулем дискретного вывода (Digital Output – DO): Принимает сигналы от процессора и управляет внешними нагрузками, такими как реле, сигнальные лампы, катушки пускателей.

Модуль 201CI-1 является ключевым компонентом для взаимодействия ПЛК с реальным миром. Работа любой автоматизированной системы, от конвейера до станка, начинается с получения или выдачи сигналов через такие модули, как дискретный модуль ввода-вывода GE 201CI-1.

- Automotive (durability testing): On automotive test rigs, the valve simulates road loads on vehicle components (e.g., shock absorbers), adjusting pressure dynamically to replicate varying terrain conditions.

- Metalworking (hydraulic presses): In large stamping presses, MOOG G413-604A regulates ram force with ±1% accuracy, ensuring consistent part quality in high-volume production of automotive body panels.

Сравнение с конкурентами

| Parameter | MOOG G413-604A | Bosch Rexroth 4WRLE | Parker D41FBE |

|---|---|---|---|

| Maximum pressure | 35 MPa | 31.5 MPa | 28 MPa |

| Flow rate | 120 L/min | 100 L/min | 90 L/min |

| Response time | ≤20 ms | ≤25 ms | ≤30 ms |

| Digital protocols | PROFINET | PROFINET | CANopen |

Модуль GE 201CI-1 представляет собой компактное устройство, устанавливаемое в крейт (шасси) контроллера Series 90-30. В зависимости от конкретной конфигурации, он может быть:

- Модулем дискретного ввода (Digital Input – DI): Принимает сигналы от внешних устройств, таких как кнопки, концевые выключатели, датчики приближения, и передает их состояние (ВКЛ/ВЫКЛ) в процессор контроллера.

- Модулем дискретного вывода (Digital Output – DO): Принимает сигналы от процессора и управляет внешними нагрузками, такими как реле, сигнальные лампы, катушки пускателей.

Модуль 201CI-1 является ключевым компонентом для взаимодействия ПЛК с реальным миром. Работа любой автоматизированной системы, от конвейера до станка, начинается с получения или выдачи сигналов через такие модули, как дискретный модуль ввода-вывода GE 201CI-1.

Советы по выбору и предостережения

-

Selection recommendations:

- For systems requiring pressures up to 35 MPa and flow rates of 120 L/min — MOOG G413-604A is ideally suited, offering superior dynamic performance.

- When integrating with PROFINET-based automation systems (e.g., Siemens TIA Portal) — the valve’s native protocol support simplifies setup and reduces latency.

- In harsh environments with temperature extremes or vibration — the robust construction and IP65 rating ensure long-term reliability. Compatibility details are available at: .

Модуль GE 201CI-1 представляет собой компактное устройство, устанавливаемое в крейт (шасси) контроллера Series 90-30. В зависимости от конкретной конфигурации, он может быть:

- Модулем дискретного ввода (Digital Input – DI): Принимает сигналы от внешних устройств, таких как кнопки, концевые выключатели, датчики приближения, и передает их состояние (ВКЛ/ВЫКЛ) в процессор контроллера.

- Модулем дискретного вывода (Digital Output – DO): Принимает сигналы от процессора и управляет внешними нагрузками, такими как реле, сигнальные лампы, катушки пускателей.

Модуль 201CI-1 является ключевым компонентом для взаимодействия ПЛК с реальным миром. Работа любой автоматизированной системы, от конвейера до станка, начинается с получения или выдачи сигналов через такие модули, как дискретный модуль ввода-вывода GE 201CI-1.

-

Precautions:

- Use only recommended hydraulic fluids: Incompatible oils can damage seals in MOOG G413-604A and degrade performance.

- Maintain fluid cleanliness: Contaminant levels exceeding ISO 4406 Class 16/13 can cause spool jamming and premature wear.

- Avoid overpressurization: Exceeding 35 MPa will damage internal components and void warranty.

- Calibrate annually: Periodic calibration ensures the valve maintains ±1% flow accuracy, critical for precision applications.

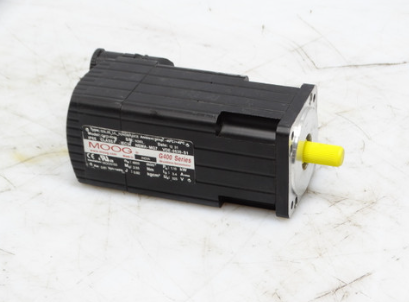

G413-604A