Описание

Product Name

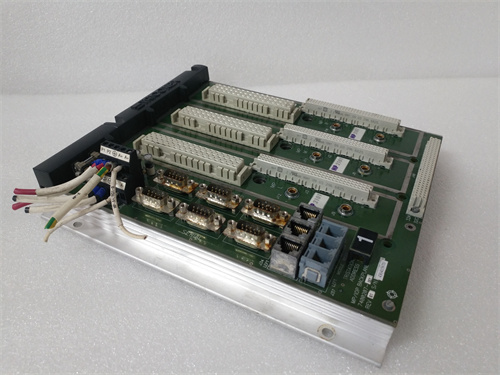

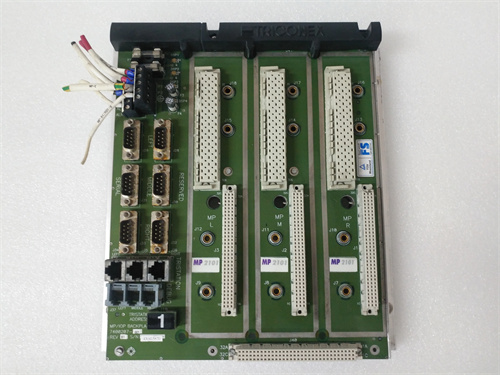

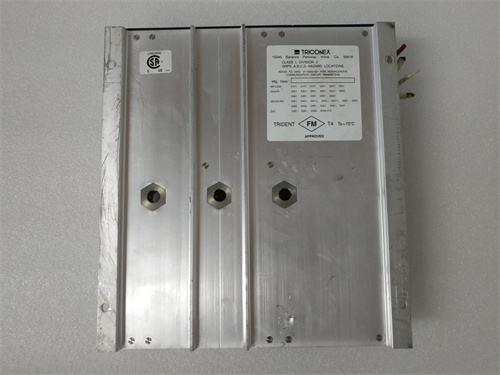

TRICONEX 2101

Product Description

The TRICONEX 2101 is a robust and highly reliable safety instrumented system designed for critical applications in the automation industry. This model is part of the TRICONEX family, which is known for its high-performance safety systems. The TRICONEX 2101 offers advanced features that enable seamless integration into complex control environments.

Designed for redundancy and fail-safe operations, the TRICONEX 2101 ensures that automated processes run smoothly without compromising safety. It is equipped with cutting-edge technology that includes real-time monitoring and diagnostic capabilities, making it an ideal choice for industries requiring stringent safety standards.

Product Parameters

- Model: TRICONEX 2101

- Input Voltage: 24 VDC

- Communication Protocols: MODBUS, ControlNet, Ethernet/IP

- Operating Temperature Range: -40°C to 70°C

- Safety Integrity Level (SIL): SIL 3

- Dimensions: 12.5 in x 6 in x 3 in

- Weight: 3.5 lbs

Advantages and Features

The TRICONEX 2101 stands out with its several advantages:

- High Reliability: The system is engineered for maximum uptime and reliability, ensuring that safety-critical functions are always operational.

- Modular Design: The modularity of the TRICONEX 2101 allows for easy upgrades and maintenance.

- Improved Diagnostics: This product features advanced diagnostic capabilities that help in troubleshooting and maintenance planning.

- Flexible Configuration: It supports multiple configurations and can be adapted to various safety applications.

- Industry Standard Compliance: The TRICONEX 2101 meets international safety standards, ensuring its suitability for global applications.

Application Fields and Case Examples

The TRICONEX 2101 is widely used in various industries including:

- Oil and Gas: For monitoring and controlling safety systems in drilling and production operations.

- Chemical Plants: To ensure compliance with safety regulations in hazardous chemical processes.

- Power Generation: For safeguarding critical components of power plants.

- Pharmaceutical Manufacturing: Helps maintain safety and compliance in drug production processes.

A notable case example involves a large oil refinery utilizing the TRICONEX 2101 to monitor multiple safety functions in real-time, significantly reducing their incident rate and enhancing overall safety performance.

Competitive Comparison

Compared to its competitors, the TRICONEX 2101 offers superior diagnostics and reliability. While other systems may provide basic safety functions, the TRICONEX 2101 incorporates advanced features that set it apart. Competitors often lack the same level of integration and versatility, making the TRICONEX 2101 a more appealing choice for organizations prioritizing safety in automation.

Selection Suggestions

When selecting a safety instrumented system, consider the following:

- Evaluate safety requirements specific to your application.

- Assess the compatibility of TRICONEX 2101 with existing systems and protocols.

- Analyze the cost-effectiveness of long-term maintenance and support that comes with the TRICONEX 2101.

- Review available diagnostics and support features, making sure they align with your operational needs.

Important Considerations

Ensure that a thorough risk assessment has been conducted prior to installation of the TRICONEX 2101. Understand the specific environmental conditions it will be exposed to, including potential temperature extremes and electrical interferences. Regular maintenance and periodic testing of the safety systems are also essential to maintain the effectiveness of the TRICONEX 2101.

We are your trusted partner and offer sales and technical support for the TRICONEX 2101 and other automation spare parts. We provide special discount prices to serve you better. Please contact us, and we will be glad to assist you.

TRICONEX+2101

| IC697CPX935 GE PLC |

| IC693CPU366 GE PLC |

| IC693CPU367 GE PLC |

| IC694MDL645 GE PLC |

| IC694MDL646 PLC |

| GE IC693CPU370 PLC |

| IC694MDL648 GE |

| IC694MDL654 DCS GE |

| IC694MDL655 GE PLC |

| IC694MDL658 PLC GE |

| IC694MDL730 PLC GE |

| IC694MDL732 PLC |

| GE IC694MDL734 PLC |

| GE IC694MDL740 PLC |

| GE IC694MDL741 PLC |

| IC694MDL742 GE PLC |

| IC694MDL752 PLC GE |

| IC694MDL753 GE CPU |

| GE IC694MDL930 PLC |

| IC694MDL931 GE PLC |

| GE IC694MDL940 I/O |

| IC693CPU372 GE |

| 1C31203G01 1C31204G01 PLC |

| EMERSON 1C31205G01 |

| EMERSON 3A99190G01 I/O |

| 5X00167G01 / 1X00188H01 HARTEMERSON |

| 5X00058G01 / 5X00059G01 [HART}PLC |

| 5X00106G01 / 5X00109G02 HART EMERSON |

| 5X00062G01 / 5X00063G01 HARTPLC |

| 5X00225G01 |

| 5X00241G02 / 5X00226G01/02 -OCR400 EMERSON |

| 5X00105G14 / 3A99190G01 -OCR161 EMERSON |

| 5X00481G01 / 5X00226G03 -OCR1100 EMERSON |

| EMERSON 5X0026144G01 |

| EMERSON 5X00301G01 / 5X00327G01 ( |

| EMERSON 5X00497G01 PLC |

| 5X00300G01 / 5X00321G01 EMERSON |

| 5X00501G01 EMERSON |

| 5X00502G01 EMERSON |

| EMERSON 1X00707H01 |

| EMERSON 3A41491H96 |

| EMERSON 5X00525G03 |

| EMERSON 5X00529G02 PLC |

| EMERSON 5X00241G01 PLC |

| EMERSON 5X00589G01 |

| EMERSON 5X00489G01 1P00159G01) |