Описание

Product Name:

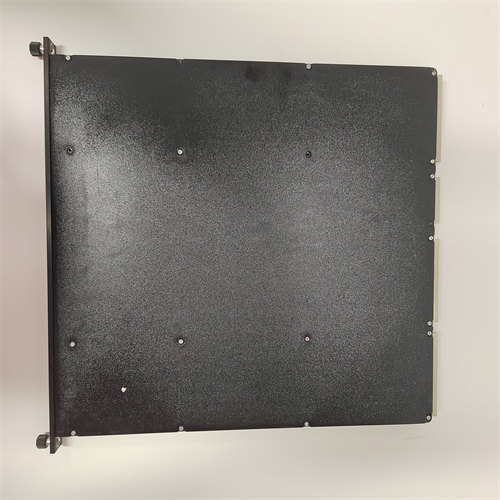

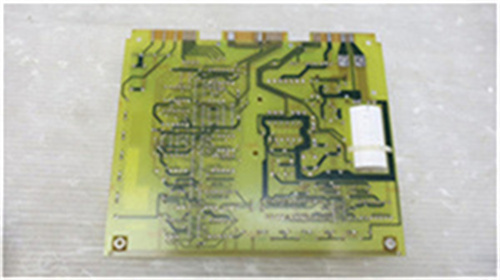

TRICONEX 3700A DCS/PLC Module

Product Description:

The TRICONEX 3700A is a Distributed Control System (DCS) and Programmable Logic Controller (PLC) module designed by Triconex, which is now part of Emerson Automation Solutions. The 3700A module is widely used in critical safety and process control systems, especially in industries like oil and gas, chemical processing, power generation, and pharmaceuticals. It provides high-reliability control, monitoring, and data processing capabilities, ensuring safety, redundancy, and fault tolerance in harsh industrial environments.

The 3700A module is a part of the Tricon platform, a well-known and reliable safety instrumented system (SIS). With its Triple Modular Redundancy (TMR) architecture, the module ensures continuous operation and safety, offering high uptime, fault detection, and error correction in industrial automation systems.

Key Features:

- Triple Modular Redundancy (TMR): Ensures high availability and system reliability by using three identical control channels, where any single failure is tolerated without affecting system performance.

- Safety Integrity: Ideal for Safety Instrumented Systems (SIS) in applications requiring SIL 3 (Safety Integrity Level 3) or higher.

- High Availability: With TMR and built-in diagnostics, the 3700A offers 99.999% uptime, critical for industries where safety and reliability are paramount.

- Flexible I/O Options: Modular design allows for flexible configuration of digital, analog, and specialty I/O modules, tailored to specific process requirements.

- Redundant Power Supplies: Supports redundant power supplies for increased reliability and continuous operation.

- Advanced Diagnostics: Real-time diagnostics, predictive failure analysis, and built-in fault detection improve system maintenance and reduce unplanned downtime.

- Protocol Support: Compatible with a range of industry-standard communication protocols for easy integration with other control systems, including Modbus, Ethernet/IP, Profibus, and HART.

- Modular Design: The system is modular, allowing the addition of more I/O and functionality as the system grows or changes.

Product Parameters & Specifications:

1. General Specifications:

- Model: TRICONEX 3700A

- Type: DCS/PLC Module, part of a Tricon system

- Manufacturer: Emerson Automation Solutions (formerly Triconex)

- Function: Provides control, monitoring, and safety management functions in critical industrial processes.

- System Architecture: Triple Modular Redundancy (TMR) for fault tolerance and continuous operation.

- Installation: Designed for rack-mounted installations in industrial environments.

- Compatibility: Compatible with Tricon system, which includes the Tricon Safety Instrumented System (SIS), I/O modules, and communication modules.

2. Electrical Specifications:

- Operating Voltage: 24V DC or 48V DC, typical for industrial systems.

- Power Consumption: The 3700A module typically consumes between 10W to 30W, depending on the configuration and load.

- Input Voltage Range: 24V DC or 48V DC (depending on system configuration).

- Output Voltage: Provides 24V DC for I/O control (digital, analog, or discrete devices).

- I/O Voltage: Supports 24V DC for digital inputs and outputs, and typically 4-20mA or 0-10V for analog I/O signals.

3. I/O Specifications:

- Digital Inputs: Typically supports 16 to 64 digital inputs (dry contacts, digital sensors, switches).

- Digital Outputs: Provides 16 to 64 digital output channels (for actuators, relays, valves, etc.).

- Analog Inputs: Supports 4-20mA or 0-10V signals for analog devices such as temperature, pressure, and flow sensors.

- Analog Outputs: Supports 4-20mA or 0-10V for controlling devices like valves, motor speed, and other variable control devices.

- Redundancy: The I/O modules support hot swapping and redundant configurations to ensure system uptime and reliability.

4. Communication Protocols:

- Modbus: A widely-used communication protocol that allows for easy integration with other automation systems.

- Ethernet/IP: Provides fast and reliable communication over Ethernet networks, suitable for industrial automation and remote monitoring.

- Profibus: Enables communication with field devices such as smart sensors, actuators, and remote I/O devices.

- HART Communication: Supports HART-enabled devices for real-time process variable updates and diagnostics.

- Redundant Ethernet: Provides redundant Ethernet networks to ensure uninterrupted communication in critical control systems.

- RS-232/RS-485: Common industrial communication interfaces for communication with other field devices and control systems.

5. Environmental Specifications:

- Operating Temperature: Typically from -20°C to 60°C (-4°F to 140°F) to withstand varying industrial environments.

- Storage Temperature: Ranges from -40°C to 85°C (-40°F to 185°F).

- Relative Humidity: 5% to 95% non-condensing.

- Vibration Resistance: Designed to meet industrial standards for vibration resistance, typically up to 5g for continuous operation.

- Shock Resistance: Built to withstand industrial shock levels, typically up to 10g.

- Ingress Protection: Meets IP20 or IP65 depending on the enclosure used for mounting.

6. Performance Specifications:

- Scan Time: Real-time control with fast scan times in the range of 10ms to 50ms, depending on system load and configuration.

- Processor Speed: Uses 32-bit or 64-bit processors for efficient execution of control algorithms.

- Memory: The module typically includes 512MB to 4GB of memory for handling control and data processing.

- Control Capacity: Supports up to 100,000 control points depending on the system configuration and number of I/O modules.

7. Safety Features:

- SIL 3 Certification: The TRICONEX 3700A meets Safety Integrity Level (SIL 3) for safety-critical applications.

- Fault Detection: Advanced diagnostics with fault tolerance and continuous self-checking for automatic failure detection.

- Redundancy: Triple Modular Redundancy (TMR) architecture ensures that the system continues to function even if one module fails.

- Hot Swap: Modules and I/O can be swapped without disrupting system operation.

Application Examples:

- Oil & Gas Industry: Used for controlling safety and process functions in critical facilities, such as offshore platforms, pipelines, and refineries.

- Chemical Processing: Suitable for high-safety environments such as chemical reactors, mixing processes, and automated batch control systems.

- Power Generation: Applied for the automation and safety control of power plants, turbines, generators, and auxiliary systems.

- Water Treatment: Ensures reliable operation of water and wastewater treatment plants, including pump control, chemical dosing, and filtration systems.

- Pharmaceutical Manufacturing: Used in cleanroom environments and process control systems to meet stringent safety and compliance requirements.

Conclusion:

The TRICONEX 3700A DCS/PLC Module offers high-performance and high-reliability control for critical industrial applications. Its Triple Modular Redundancy (TMR) architecture ensures maximum uptime, fault tolerance, and safety, making it ideal for industries where process integrity and safety are paramount. It’s highly modular and offers flexible I/O and communication protocol support, allowing it to be easily tailored to a wide range of applications.

For detailed product manuals, configuration guidelines, and support, please refer to Emerson’s official documentation or contact their support team.