Описание

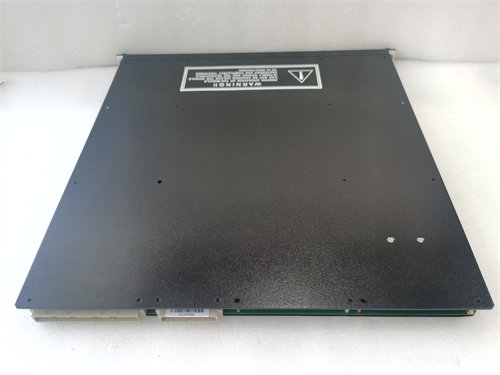

Product Name:

TRICONEX 4351A DCS PLC Module

Product Description:

The TRICONEX 4351A is a DCS PLC module designed and manufactured by Emerson as part of its Triconex Safety Instrumented System (SIS) portfolio. The 4351A module is engineered to provide high levels of safety and reliability in industrial automation applications, particularly for process industries such as oil & gas, chemical, power generation, and pharmaceuticals.

This module is typically used for input/output (I/O) processing, signal conditioning, and interfacing with field devices in safety-critical operations. The TRICONEX 4351A supports digital and analog I/O, redundancy, and advanced diagnostics, making it ideal for systems that demand high availability and fault tolerance.

The 4351A is compatible with Emerson’s Triconex TMR (Triple Modular Redundancy) architecture, which ensures the continuous and safe operation of control systems by providing a robust fault-tolerant system that maintains process safety in case of failure.

This module is designed to meet critical safety standards like IEC 61508 and SIL (Safety Integrity Level) specifications, providing a high level of reliability for industries that require stringent safety compliance.

Product Parameters:

- Model: TRICONEX 4351A

- Type: DCS PLC Module

- Manufacturer: Emerson (TRICONEX)

- Function: Input/Output processing and interfacing in Safety Instrumented Systems (SIS)

- Applications: Oil & Gas, Chemical, Power Generation, Pharmaceutical, Manufacturing

- Architecture: Triple-Modular Redundancy (TMR), ensuring fault tolerance and high availability

- Control Type: Real-time process control and safety monitoring

- I/O: Digital and Analog I/O for interfacing with field devices

Product Specifications:

General Features:

-

Triple-Modular Redundancy (TMR):

- The TRICONEX 4351A operates on TMR architecture, which is critical for achieving high system availability and fault tolerance in safety-critical applications. If one channel fails, the system continues to function using the remaining two channels.

-

Safety Compliance:

- Designed to meet international safety standards such as IEC 61508 for functional safety and SIL (Safety Integrity Level) ratings for critical processes.

- Ensures compliance with industry-specific safety requirements, helping operators achieve the necessary levels of process safety.

-

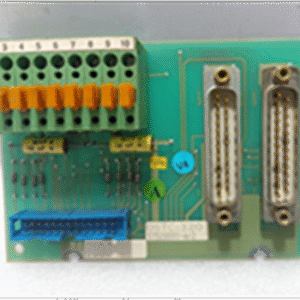

I/O Capabilities:

- Digital Inputs (DI): Accepts digital signals (e.g., from limit switches, relays) to monitor field conditions.

- Analog Inputs (AI): Processes 4-20mA signals, typically used to monitor physical parameters such as temperature, pressure, and flow.

- Digital Outputs (DO): Controls field devices such as actuators, relays, and alarms.

- Analog Outputs (AO): Provides 4-20mA output for controlling analog devices based on process conditions.

-

Advanced Diagnostics:

- Features self-diagnostics and real-time monitoring capabilities. Continuous health checks ensure that any issues in the system are detected and logged for analysis, reducing the risk of unplanned downtime.

-

Signal Conditioning:

- Signal conditioning is built-in for both analog and digital signals, ensuring precise measurements and reliable operation of field devices.

-

Real-Time Control and Data Processing:

- Supports real-time data processing to control critical industrial processes efficiently. The module ensures accurate and timely responses to input signals from field devices.

-

High Reliability:

- Designed with redundant power supplies, processors, and communication paths, the TRICONEX 4351A ensures continuous operation, even in the event of hardware failure.

-

Integration with Triconex Safety Systems:

- Fully integrated into Triconex SIS, allowing for easy configuration, monitoring, and control of safety-critical operations.

Electrical Specifications:

-

Power Supply:

- Nominal Input Voltage: Typically 24 V DC, suitable for standard industrial applications.

- Power consumption varies depending on the number of I/O channels, but the module is designed to minimize power usage for efficiency.

-

Input Types:

- Digital Inputs: Handles 16 digital input channels (configurable based on the system).

- Analog Inputs: Typically supports 8-16 4-20mA analog inputs, depending on the configuration.

-

Output Types:

- Digital Outputs: Supports 16 digital output channels.

- Analog Outputs: 4-8 4-20mA analog output channels.

-

Signal Conditioning:

- Includes signal conditioning for accurate processing of both digital and analog signals from field devices.

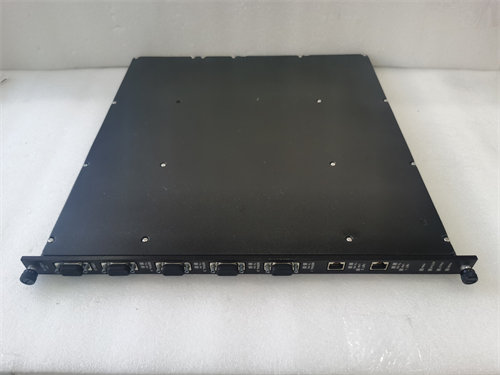

Mechanical Specifications:

-

Dimensions:

- The module is designed to fit standard 19-inch rack mounting enclosures, compatible with industrial control cabinets.

- Height: 3.5 inches (89 mm)

- Width: 6.5 inches (165 mm)

- Depth: 10 inches (254 mm)

-

Weight:

- Typically around 2-3 kg depending on the specific configuration.

-

Mounting:

- Rack-mountable within a 19-inch rack. This allows for easy installation within control panels and cabinets.

Environmental Specifications:

-

Operating Temperature:

- 0°C to 60°C (32°F to 140°F), ideal for most industrial environments where temperature control is within these limits.

-

Storage Temperature:

- Typically -40°C to 85°C (-40°F to 185°F), ensuring safe storage in diverse environments.

-

Humidity:

- Operational humidity up to 95% relative humidity, non-condensing, making it suitable for use in humid industrial environments.

-

Vibration and Shock Resistance:

- Built to handle the rigorous vibrations and shocks common in industrial environments.

-

Electromagnetic Interference (EMI) / Radio-Frequency Interference (RFI):

- The module is designed with EMI/RFI protection to operate in environments with significant electrical noise, ensuring stable communication and control.

Key Benefits:

-

Fault Tolerant and High Availability:

- The TMR architecture ensures that even if one part of the system fails, the other parts continue to operate, providing high system availability and zero downtime for safety-critical applications.

-

Built for Safety-Critical Operations:

- Designed with advanced safety features and compliance with international safety standards such as SIL and IEC 61508, ensuring the module is suitable for safety-critical industries.

-

Advanced Diagnostics and Self-Testing:

- Provides real-time diagnostics and self-testing, allowing operators to detect issues before they cause system failure, minimizing downtime and preventing costly repairs.

-

Ease of Integration:

- Integrates seamlessly with other Triconex systems and industry-standard protocols, making the module ideal for expanding or upgrading existing control and safety systems.

-

Real-Time Control:

- Supports real-time process control for both safety and operational requirements, allowing users to manage complex systems effectively.

Conclusion:

The TRICONEX 4351A DCS PLC Module is a highly reliable, fault-tolerant, and safety-compliant module designed for mission-critical operations in industries such as oil & gas, chemical processing, power generation, and manufacturing. By utilizing Triple-Modular Redundancy (TMR) architecture, it ensures that even in the event of failure, the system continues to operate, maintaining process safety and reducing downtime. It offers a wide range of I/O capabilities, advanced diagnostics, and signal conditioning, making it a perfect choice for industries that require continuous, safe, and efficient operations.