Описание

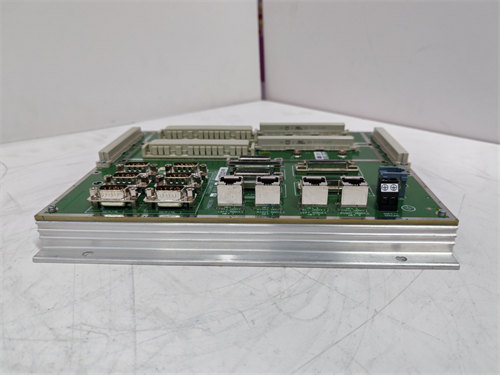

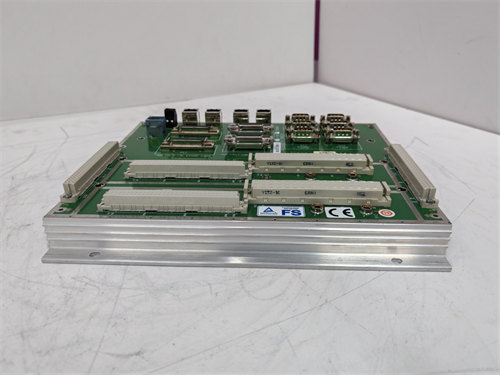

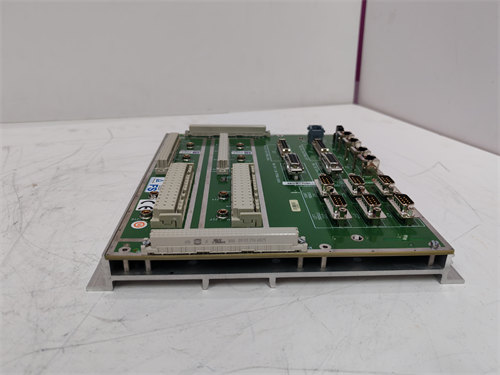

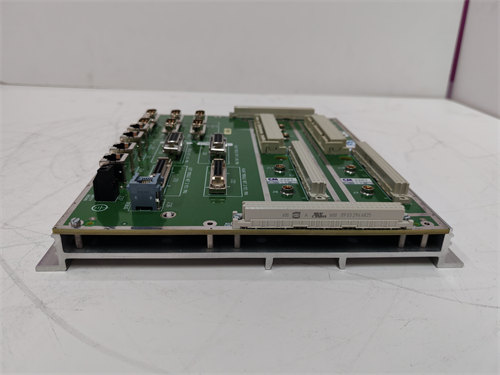

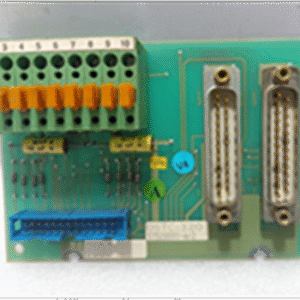

The TRICONEX CM2201 7400206-100 is a key component in the Triconex family of safety systems, widely used for industrial automation and control in critical process applications. Triconex is a brand under Schneider Electric and is known for its highly reliable and redundant Safety Instrumented Systems (SIS) and Distributed Control Systems (DCS). The CM2201 is a communications module that plays a central role in facilitating communication between the Triconex safety system and external systems.

Here’s a breakdown of the CM2201 7400206-100 module:

Product Name:

TRICONEX CM2201 7400206-100 Communications Module

Product Description:

The TRICONEX CM2201 7400206-100 is a communications module that enables seamless data exchange between Triconex Safety Instrumented Systems (SIS) and other control systems, such as DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), or SCADA (Supervisory Control and Data Acquisition) systems.

The module supports a range of industrial communication protocols, enabling the integration of Triconex systems into diverse operational environments where high availability and safety are paramount. It is a key component in the Triconex Tricon and Tricon CX systems, providing an interface for real-time data monitoring and control.

The CM2201 module is designed to ensure that critical safety information is accurately relayed between the Tricon system and other systems, offering high reliability, fault tolerance, and security. This communication functionality is essential in industries such as oil and gas, chemical processing, power generation, and refining, where safety and operational continuity are non-negotiable.

Key Features:

- High-Availability Communication: Ensures continuous, real-time communication between Triconex systems and other devices in the control network.

- Redundancy: Built to handle redundancy configurations, ensuring high availability in critical applications.

- Flexible Protocol Support: Supports Modbus TCP, Ethernet/IP, and PROFIBUS for communication with a wide variety of external systems.

- Real-Time Data Exchange: Facilitates near-instantaneous exchange of critical data between control systems, which is crucial for safety and process control.

- Built-in Diagnostics: Provides detailed diagnostics to help maintain the system’s health and reduce downtime.

- Ease of Integration: Can be easily integrated with existing Triconex safety systems and other industrial control networks.

- Compact Design: Space-saving design that can fit into existing control panels or racks.

Product Parameters and Specifications:

1. Model Information:

- Model Number: CM2201 7400206-100

- Module Type: Communication Module

- Brand: Triconex (Schneider Electric)

- Series: Part of the Triconex Tricon and Tricon CX system families.

2. I/O Capacity and Functionality:

- Communication Ports:

- Typically has Ethernet and serial communication ports.

- Modbus TCP, Ethernet/IP, and PROFIBUS communication protocols are typically supported for integration with other control systems.

- External Connections: It connects seamlessly with other DCS or PLC systems for real-time data transfer.

- Fieldbus Integration: Compatible with a range of industrial fieldbus standards for easy integration with industrial control systems.

3. Electrical Specifications:

- Input Voltage: Typically operates on 24V DC (common for Triconex systems).

- Power Consumption: Relatively low, but specific consumption depends on the operational configuration and number of communication ports in use.

- Input/Output Isolation: Ensures electrical isolation between internal control systems and external devices for safety.

4. Communication Protocols:

- Modbus TCP/IP: Allows communication with Modbus-compatible devices across Ethernet networks.

- Ethernet/IP: Allows integration with Ethernet/IP networks for communication with PLCs, controllers, and other devices.

- PROFIBUS: Compatible with PROFIBUS fieldbus networks, which is widely used in industrial automation for connecting field devices.

5. Environmental Specifications:

- Operating Temperature: Generally, the module operates in the temperature range of 0°C to 60°C. Extended temperature versions may be available for harsher environments.

- Storage Temperature: Typically -40°C to 85°C for storage.

- Humidity: Designed for use in environments with 5% to 95% relative humidity (non-condensing).

- Vibration and Shock Resistance: The module is rated to withstand industrial-grade vibrations and mechanical shock typical in industrial environments.

6. Diagnostics and Reliability:

- Self-Diagnostics: Provides internal diagnostics to ensure proper functionality and to detect issues like communication failures, network errors, or faulty connections.

- LED Indicators: Equipped with LED indicators for quick visual diagnostics of status, network connectivity, and error conditions.

- Error Detection and Alerts: Capable of detecting faults such as open circuits, short circuits, communication errors, and other system malfunctions.

7. Certifications and Compliance:

- CE Marking: Complies with European Union EMC (Electromagnetic Compatibility) and Safety directives.

- UL Approval: Available in UL-rated configurations for North American markets.

- SIL Capability: Meets Safety Integrity Level (SIL) requirements, making it suitable for use in SIS applications where high safety standards are required.

- Ex-proof / Hazardous Locations: May be available in variants designed for use in hazardous locations (specific models may need to be verified for ATEX or UL Ex certifications).

8. Mounting and Integration:

- Rack-Mountable: The CM2201 module is designed to be mounted in 19-inch racks or control panels for easy integration into existing systems.

- Field Installable: Can be easily installed and replaced in the field without significant downtime or reconfiguration.

- Hot Swappable: Depending on the configuration, it may be hot-swappable in certain systems.

Applications:

The TRICONEX CM2201 7400206-100 module is used in industries where safety and reliability are critical, such as:

- Oil and Gas:

- Used for safety and control in both upstream (drilling) and downstream (refining, processing) processes.

- Chemical Processing:

- Ensures real-time communication between safety systems and process control systems to protect against hazardous conditions.

- Power Generation:

- Monitors and controls safety-critical systems like boilers, turbines, and reactors in power plants.

- Pharmaceutical and Food Processing:

- Ensures compliance with safety standards while maintaining reliable communication between control systems in regulated environments.

- Mining:

- Provides real-time communication for safety and automation in mining operations.

Conclusion:

The TRICONEX CM2201 7400206-100 communication module is a vital component in Triconex’s safety systems, facilitating high-performance, real-time communication between safety and control systems. With support for various industrial communication protocols, redundant design, and a focus on safety integrity, this module is ideal for high-reliability applications in industries like oil and gas, power generation, chemical processing, and more.

Its diagnostic features, ease of integration, and wide range of supported communication st